Description

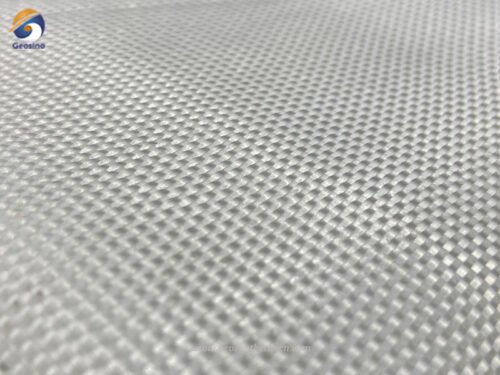

PP woven geotextile, also known as polypropylene woven geotextile fabric, is a permeable fabric made from polypropylene (PP) material. It is commonly used in geotechnical engineering and construction applications. PP woven geotextile offers permeability and filtration capabilities, making it suitable for various purposes such as separation, reinforcement, drainage, and erosion control. This geotextile is known for its durability, strength, and resistance to environmental factors. It provides cost-effective solutions for stabilizing soil, reinforcing structures, preventing erosion, and improving overall project performance. With its permeability and geotechnical properties, GEOSINCERE PP woven geotextile is a reliable choice for a wide range of geotechnical and construction projects.

1. What Is A PP Woven Geotextile?

PP woven geotextile is a type of geotextile made from polypropylene (PP) material. It is manufactured by weaving polypropylene tapes or filaments together to create a strong and durable fabric. The GEOSINCERE brand offers high-quality PP woven geotextiles designed specifically for construction applications, providing functions such as separation, filtration, reinforcement, protection, and drainage.

The manufacturing process of PP woven geotextile involves using virgin polypropylene fiber yarns and weaving them into a textile-shaped material with high tensile strength. Automatic production lines ensure efficient and precise weaving, allowing for different weaving opening sizes to accommodate specific project requirements.

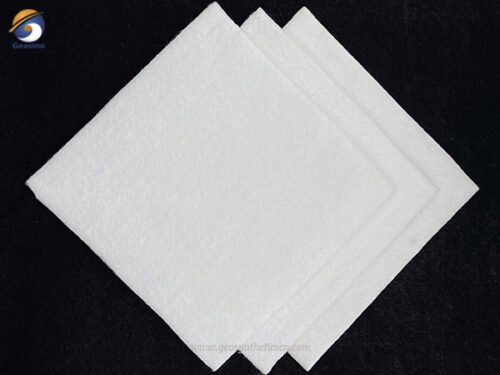

One of the key advantages of GEOSINCERE’s PP woven geotextile is its lightweight nature, which makes it easy to handle and transport. Despite its lightweight, it possesses excellent tensile strength, minimal elongation, and exceptional stability. These properties contribute to its effectiveness and cost-efficiency in stabilizing slopes, reinforcing soil, and controlling erosion.

GEOSINCERE offers a range of PP woven geotextiles with varying tensile strengths, woven structures, and sizes to cater to the specific needs of road construction and embankment projects. This versatility allows engineers and contractors to choose the most suitable geotextile for their application, ensuring optimal performance and durability.

GEOSINCERE PP woven geotextile in construction projects provides numerous benefits. Its high-quality construction, reliable performance, and customizable options make it a trusted choice for geosynthetic applications. It contributes to the stability and longevity of infrastructure projects, effectively addressing soil reinforcement, slope stabilization, and erosion control requirements.

GEOSINCERE’s PP woven geotextile is a durable, cost-effective, and versatile solution for various construction applications. Its lightweight yet strong characteristics make it an ideal choice for enhancing the performance and longevity of geotechnical projects.

2. Technical Data of PP Woven Geotextile

| Property |

BTW20-15 |

GEOSINCERE30-20 |

GEOSINCERE40-28 |

GEOSINCERE50-35 |

GEOSINCERE60-42 |

GEOSINCERE80-56 |

GEOSINCERE100-70 |

| Breaking Strength in MD KN/m |

20 |

30 |

40 |

50 |

60 |

80 |

100 |

| Breaking Strength in MD KN/m |

15 |

22 |

28 |

35 |

42 |

56 |

70 |

| Elongation Rate |

25% |

| Trapezoidal Tearing Strength, KN >= |

0.2 |

0.27 |

0.34 |

0.41 |

0.48 |

0.6 |

0.72 |

| CBR Mullen Burst Strength KN |

1.6 |

2.4 |

3.2 |

4 |

4.8 |

6 |

7.5 |

| Vertical Permeability cm/s |

10-1~10-4 |

| Sieve Size O90 (O95) (mm) |

0.07~0.50 |

| Unit Weight (g/m2) |

120 |

160 |

200 |

240 |

280 |

340 |

400 |

| Variation |

±10% |

3. What Are Advantages of PP Woven Geotextile?

PP woven geotextiles offer several advantages that make them a preferred choice for various geotechnical and construction applications. Here are the advantages of PP woven geotextiles:

3.1 High Modulus and High Tensile Strength at Low Elongation

PP woven geotextiles possess high modulus and tensile strength, providing exceptional reinforcement capabilities. They can withstand heavy loads and maintain their integrity even under low elongation conditions, ensuring the stability and safety of structures.

3.2 High Permittivity and Water Flow Rates

PP woven geotextiles have high permittivity, allowing for efficient water flow and drainage. This feature helps prevent water buildup, mitigates the risk of soil saturation, and promotes proper soil moisture balance.

3.3 Excellent Resistance to Mineral Acids

PP woven geotextiles exhibit excellent resistance to mineral acids, making them suitable for applications where exposure to acidic environments is anticipated. This resistance ensures the long-term durability and performance of the geotextile in challenging conditions.

3.4 Good Durability to Ensure Structure Safety

PP woven geotextiles are highly durable, providing long-lasting performance in demanding environments. Their durability ensures the safety and stability of structures, as they can withstand environmental factors, chemical exposure, and mechanical stresses.

3.5 Excellent Chemical Resistance, Even in Alkaline Soils

PP woven geotextiles demonstrate excellent chemical resistance, including resistance to alkaline soils. This feature allows them to maintain their effectiveness and integrity, even in aggressive chemical environments, ensuring their long-term functionality.

3.6 High Quality and Durability to Ensure Structure Safety

PP woven geotextiles are manufactured with a focus on high quality and durability. This ensures their ability to withstand rigorous conditions, including heavy loads, soil movement, and exposure to UV radiation, providing reliable and long-lasting reinforcement for structures.

3.7 High Mechanical Performance

PP woven geotextiles offer high mechanical performance, including strength, tear resistance, and load-bearing capacity. This mechanical strength enhances their effectiveness in stabilizing and reinforcing soil, preventing erosion, and enhancing the structural integrity of projects.

3.8 Proven Performance for Most Stabilization and Reinforcement Applications

PP woven geotextiles have a track record of proven performance in a wide range of stabilization and reinforcement applications. Their reliability and effectiveness have been demonstrated in various civil engineering projects, providing confidence in their use for diverse geotechnical needs.

3.9 Extensive Range of Size, Thickness, and Grades

PP woven geotextiles are available in a wide range of sizes, thicknesses, and grades. This variety allows for flexibility and customization, enabling engineers and contractors to select the most suitable geotextile for their specific requirements.

3.10 Ensured Quality, Competitive Factory Price, Fast Deliver

GEOSINCERE prioritizes quality control, ensuring that the geotextiles meet stringent standards. Additionally, they offer competitive factory pricing, making them a cost-effective solution for geotechnical applications. With efficient production and supply chains, fast delivery of PP woven geotextiles can be ensured, meeting project timelines and requirements.

the advantages of PP woven geotextiles encompass their strength, durability, chemical resistance, water flow capabilities, proven performance, customization options, quality assurance, competitive pricing, and timely delivery. These advantages make PP woven geotextiles a reliable and efficient choice for a wide range of stabilization and reinforcement applications in the construction industry.

4. What Are PP Woven Geotextile Used For?

PP woven geotextile provides a cost-effective solution, offering a wide range of options in terms of tensile strengths and woven opening sizes. This versatility allows it to effectively meet the extensive requirements of stabilization and reinforcement projects. Whether the project demands high tensile strength or specific woven opening sizes, PP woven geotextile can be tailored to suit the needs of the application. Its affordability combined with its ability to provide stability and reinforcement make it a practical choice for various construction projects. With its availability in different specifications, PP woven geotextile ensures that project requirements are met with precision, providing reliable support and durability.

- Earthwork Construction

- Steep side slope reinforcement

- Embankment stablization and reonforcement

- Bridging over sinkholes

- Roadway and Railway Construction

- Base Reinforcement

- Subgrade stabilization

- Water infrastructure

- Marine and coastal construction

- Seawalls and breakwaters

- Riverbank and channel protection

- Airport runway

- Beach reclamation

5. About GEOSINCERE

GEOSINCERE has been dedicated to manufacturing wholesaling geotexitle and geosynthetics products and solutions to worldwide customers since its foundation in 2007. Our main innovative, high quality products include geotextiles, geomembranes, geogrids, geocells, geosynthetic clay liners, and drainage boards, etc. GEOSINCERE customers are from America, Australia, France, Sweden, UK, Hong Kong, Hungary, New Zealand, Poland, Mexico, Ecuador, Brazil, Pakistan, Bangladesh, Thailand, Vietnam, Malaysia, Indonesia, Singapore, Philippines, Sri Lanka, India, UAE, Saudi Arabia, Qatar, Kenya, Ghana, Ethiopia, Somalia, Nigeria, South Africa, Swaziland, Mongolia, etc.

GEOSINCERE offers both high quality geosynthetic products but also professional design and installation service. OEM, ODM, custom development and fabrication are also available. If you have any questions or inquiries, please contact us, we will reply as soon as possible.