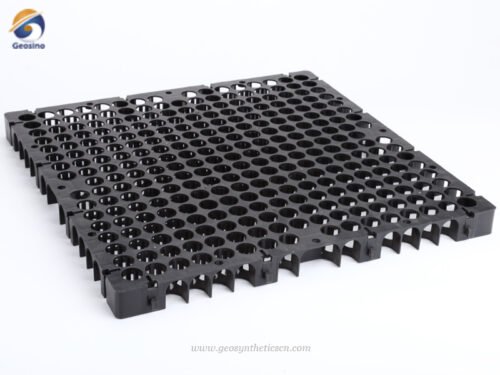

Sheet drain, also known as dimple drain sheets, is a three-dimensional plate with bumps or holes made of high-density polyethylene material through a special manufacturing process. The composite sheet drain can be connected to waterproof materials, concrete or wood with metal pins, construction adhesive or double-sided tape to form an efficient filtration and drainage system. Sheet drains are an ideal drainage solution for foundation walls, behind retaining walls and in green roof applications.

Sheet Drain

Description

Sheet drain, also known as dimple drain sheets, is a three-dimensional plate with bumps or holes made of high-density polyethylene (HDPE) material through a special manufacturing process. The dimple drainage structure allows for a high flow rate while an outer layer of permeable geotextile prevents debris from entering the drainage channel. The HDPE sheet drain can be bonded with non-woven geotextile by hot pressing on one or both sides. This combination offers excellent compressive strength, drainage performance, and resistance to wear and slippage, effectively preventing sand and gravel particles from entering the drainage sheets. The unique concave-convex hollow vertical rib structure of the storage and drainage plate quickly and effectively drains rainwater, reducing hydrostatic pressure in waterproof layers for active waterproofing. Sheet drains are ideal for foundation walls, behind retaining walls, and green roof applications, connecting seamlessly with various materials using metal pins, construction adhesive, or double-sided tape to form efficient filtration and drainage systems.

Sheet Drain Specifications

| Item | Unit | BDS10 | BDS12 | BDS122 |

|---|---|---|---|---|

| Core Properties | ||||

| Core structure |

Single Cuspated Flat Back |

Single Cuspated Flat Back | Single Cuspated Flat Back | |

| Cuspation Height | mm | 10 | 12 | 12 |

| Core Material | Virgin HDPE | Virgin HDPE | Virgin HDPE | |

| Material Thickness | mm | 1 | 1 | 1.2 |

| Geotextile Properties | ||||

| Structure | Needle Punched, Heat Pressed | Needle Punched, Heat Pressed | Needle Punched, Heat Pressed | |

| Type | PET Filament | PET Filament | PET Filament | |

| Weight | gsm | 200 | 150 | 250 |

| Color | gsm | White | Grey | Black |

| Sheet Drain Properties | ||||

| Discharge Capacity | L/m/min | 145 | 155 | 185 |

| Compressive strength | kPa | 280 | 260 | 310 |

| Roll Width | m | 0.9 | 1.2 | 1.4 |

| Roll Length | m | 25 | 25 | 25 |

Sheet Drain Features

- Has the dual characteristics of HDPE and geotextile

- Excellent Flow Capacity

- Superior water collection ability

- High compressive strength

- Good filtering performance

- Excellent drainage and stagnant water performance

- Good wear resistance

- Shotcrete reinforcement

- Minimal Excavation

- Light weight

- Easy to transport

Sheet Drain Applications

- Greening project. Roof garden, vertical greening, sloping roof greening, football field, golf course, etc.;

- Municipal engineering. Airports, roads and subgrades, subways, tunnels, landfills.

- Construction engineering. The upper or lower floor of the building foundation, the interior and exterior walls and bottom of the basement, the roof, the impermeable and thermal insulation layer of the roof, etc.

- Water conservancy projects. Anti-seepage water of reservoirs, reservoirs, artificial lakes.

- Traffic engineering. Highways, railway subgrades, dams and slope protection layers.

About GEOSINCERE

GEOSINCERE has been dedicated to manufacturing wholesaling geotexitle and geosynthetics products and solutions to worldwide customers since its foundation in 2007. Our main innovative, high quality products include geotextiles, geomembranes, geogrids, geocells, geosynthetic clay liners, and drainage products, etc. GEOSINCERE customers are from more than 1000 countries including America, Australia, France, Sweden, UK, Hong Kong, Hungary, New Zealand, Poland, Mexico, Ecuador, Brazil, Pakistan, Bangladesh, Thailand, Vietnam, Malaysia, Indonesia, Singapore, Philippines, Sri Lanka, India, UAE, Saudi Arabia, Qatar, Kenya, Ghana, Ethiopia, Somalia, Nigeria, South Africa, Swaziland, Mongolia, etc.

GEOSINCERE offers both high quality geosynthetic products but also professional design and installation service. OEM, ODM, custom development and fabrication are also available. If you have any questions or inquiries, please fill and submit the following form, we will reply as soon as possible.