Description

Steel plastic geogrids are known for their exceptional strength, excellent friction coefficient, and robust bearing capacity. They are widely used for reinforcing retaining walls, slopes, and roads. GEOSINCERE, a leading manufacturer and supplier of geogrids, provides high-quality custom steel plastic geogrids at competitive factory prices.

With GEOSINCERE’s expertise in geogrid manufacturing, customers can rely on the durability and performance of their steel plastic geogrids. These geogrids offer enhanced reinforcement and stability, making them ideal for various engineering applications.

GEOSINCERE understands the importance of cost-effectiveness for their customers, and therefore, they offer their custom steel plastic geogrids at the best factory price. This ensures that customers receive reliable and high-quality geogrids without compromising on their budget.

By choosing GEOSINCERE as their geogrid supplier, you can expect top-notch products that meet their specific project requirements, backed by competitive pricing and a commitment to quality.

1. What Is A Steel Plastic Geogrid?

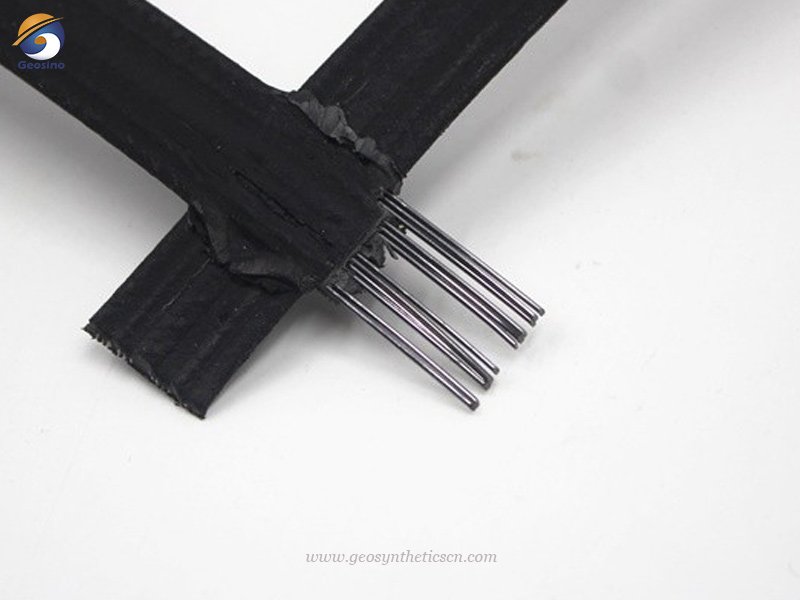

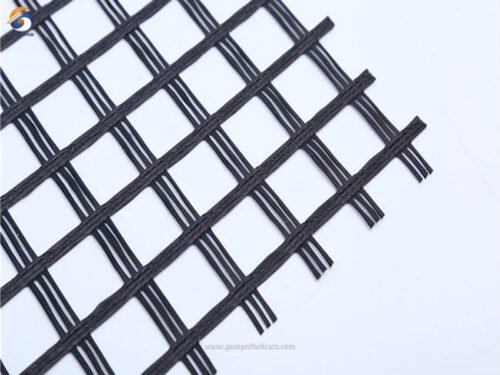

A steel plastic geogrid, also referred to as a steel composite geogrid, is a strong strip composed of high-strength steel wire enveloped in high-density polyethylene and other additives through specialized manufacturing processes. This geogrid comprises a geosynthetic material with steel strips arranged longitudinally and horizontally at specific intervals, which are then fused together using ultrasonic welding technology. The mesh diameter and steel wire tension of the geogrid can be customized to meet specific project requirements. It offers numerous advantages, including durability, high strength, and a robust bearing capacity. Within a certain strain capacity, it can achieve an exceptionally high tensile modulus.

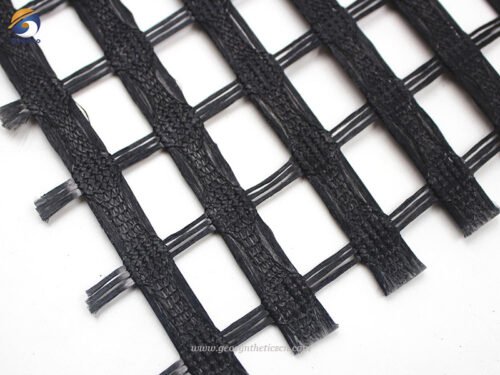

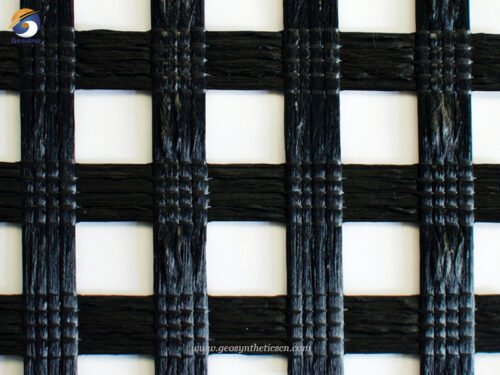

The steel-plastic geogrid is a two-dimensional mesh formed predominantly by high-strength tensile steel wire and polyethylene. Its rough surface enhances the friction between the geogrid and the ground, thereby improving soil stability. The warp and weft ribs work in tandem to achieve soil interlocking and reinforcement. With its high friction coefficient and bearing capacity, the steel-plastic composite geogrid significantly enhances the interlocking and occluding bearing capacity of foundations. It effectively restricts lateral soil displacement and enhances overall stability.

This two-dimensional mesh structure of the steel-plastic geogrid provides an ideal interlocking system for carrying and distributing forces more effectively, making it suitable for reinforcing large areas subjected to long-term loads.

Steel-plastic geogrid finds wide application in soft ground engineering projects such as highways, railroads, dams, ports, and tall retaining walls. It is also utilized for safety protection in underground coal mines.

Furthermore, the steel composite geogrid facilitates the transfer of upper loads, ensuring even distribution to the soft soil at the foundation’s bottom. It can even absorb high-intensity vibration energy. These features make it an ideal geosynthetic material for civil engineering stabilization and reinforcement applications.

The steel plastic geogrid exhibits excellent corrosion resistance and wear resistance. It can withstand the potential damage caused by rolling equipment. Compared to plastic geogrids, this type of geogrid is more durable. Additionally, the rough surface of the steel plastic geogrid significantly increases the friction coefficient between the geogrid and the soil. This high friction coefficient enhances the bearing capacity and stability of the soil. As a result, the steel plastic geogrid effectively enhances the foundation’s bearing capacity and prevents lateral displacement of the soil.

To summarize, the steel-plastic geogrid combines durability, high strength, soil interlocking capabilities, load transfer efficiency, and vibration absorption, making it a reliable choice for enhancing the stability and performance of various construction projects. It provides an effective solution for improving foundation stability, restraining soil displacement, and optimizing load distribution in civil engineering applications.

2. Technical Data of Steel Plastic Geogrid

| Item |

GSO30-30 |

GSO40-40 |

GSO50-50 |

GSO60-60 |

GSO80-80 |

GSO100-100 |

GSO150-150 |

| Tensile Strength (kN/m) |

Longitudinal |

≥30 |

≥40 |

≥50 |

≥60 |

≥80 |

≥100 |

≥150 |

| Transverse |

≥30 |

≥40 |

≥50 |

≥60 |

≥80 |

≥100 |

≥150 |

| Elongation Rate (%) |

Longitudinal |

≤2 |

| Transverse |

≤2 |

| Strength at 1% elongation (KN/m) |

Longitudinal |

≥20 |

≥32 |

≥40 |

≥48 |

≥63 |

≥81 |

≥125 |

| Transverse |

≥20 |

≥32 |

≥40 |

≥48 |

≥63 |

≥81 |

≥125 |

| Limit peel force at welded bonded point N |

|

≥100 |

≥100 |

≥100 |

≥100 |

≥100 |

≥100 |

≥100 |

3. What Are Advantages of Steel Plastic Geogrid

Steel plastic geogrid offers several advantages that make it a preferred choice for various engineering applications. Here are the advantages of steel plastic geogrid:

3.1 Excellent mechanical properties and long-term stability

Steel plastic geogrid exhibits exceptional mechanical strength, ensuring long-term stability and structural integrity.

3.2 High wear resistance

The geogrid’s composition and design provide it with high resistance to wear, making it suitable for applications where abrasive forces are present.

3.3 Anti-corrosion resistance

Steel plastic geogrid is resistant to corrosion, protecting it from degradation in harsh environments and increasing its lifespan.

3.4 Balanced vertical and horizontal strength

The geogrid’s design ensures balanced strength in both vertical and horizontal directions, providing uniform reinforcement and stability.

3.5 High strength, lower elongation

The geogrid’s high-strength steel wire construction offers superior tensile strength while minimizing elongation, ensuring structural integrity under load.

3.6 Strong tearing resistance

Steel plastic geogrid has robust tearing resistance, preventing the propagation of cracks or damage.

3.7 Excellent resistance to differential settlement

The geogrid effectively resists differential settlement, maintaining stability and preventing uneven settlement in the soil.

3.8 Excellent dimensional stability

Steel plastic geogrid maintains its shape and dimensions over time, even under varying environmental conditions, ensuring consistent performance.

3.9 Strong bearing capacity

The geogrid enhances the soil’s bearing capacity, allowing it to support heavier loads and distribute them more effectively.

3.10 High friction coefficient

The geogrid’s rough surface increases the friction coefficient between the geogrid and the soil, improving stability and preventing soil displacement.

3.11 High resistance to dynamic impact load and vibration activity

Steel plastic geogrid can withstand dynamic impact loads and vibrations, making it suitable for applications where such forces are present.

3.12 Quick and easy to install

Steel plastic geogrid is designed for easy installation, saving time and labor during construction projects.

Steel plastic geogrid offers a combination of strength, durability, stability, and cost-effectiveness, making it a reliable geosynthetic material for various civil engineering applications.

4. What Is Steel Plastic Geogrid Used For?

Steel plastic geogrid finds extensive use in various areas and applications, including:

4.1 Roads, Highways, and Railways

Steel plastic geogrid is commonly employed in the construction and reinforcement of roads, highways, railways, and bridge abutments. It helps to enhance the load-bearing capacity and stability of the infrastructure, ensuring long-term performance.

4.2 Retaining Walls and Slope Protection

The geogrid is used for reinforcing retaining walls and providing slope protection. It prevents soil erosion, improves slope stability, and enhances the overall structural integrity of these engineering structures.

4.3 Docks and Wharfs

In marine and waterfront construction, steel plastic geogrid is utilized for reinforcing docks, wharfs, and other waterfront structures. It helps to distribute loads and improve the stability of these structures in challenging environments.

4.4 Reservoirs and Dams

Steel plastic geogrid is applied in the construction of reservoirs and dams to reinforce the embankments and provide stability. It helps to withstand the weight of the water and prevents soil displacement.

4.5 Parking Lots and Airport Runways

The geogrid is used in the construction of parking lots and airport runways to improve the load-bearing capacity of the surface. It helps to distribute loads more effectively and reduces the risk of deformation or rutting.

4.6 Soft Soil Foundation Reinforcement

In areas with weak or soft soil conditions, steel plastic geogrid is employed to strengthen the foundation and improve its load-bearing capacity. It provides stability and prevents settlement or deformation of the structure.

4.7 Sports Fields

Steel plastic geogrid is utilized in the construction of sports fields to enhance their durability and load-bearing capacity. It helps to prevent soil compaction and maintains a stable playing surface.

4.8 Embankments and Flood Control Canals

The geogrid is used for reinforcing embankments and flood control canals, improving their stability and preventing erosion. It ensures the long-term performance of these structures under varying water levels.

Steel plastic geogrid is extensively used in various civil engineering projects where enhanced strength, stability, and load-bearing capacity are required. Its versatility and durability make it a valuable geosynthetic material for reinforcing and stabilizing a wide range of structures and foundations.

5. About GEOSINCERE

GEOSINCERE has been dedicated to manufacturing wholesaling geotexitle and geosynthetics products and solutions to worldwide customers since its foundation in 2007. Our main innovative, high quality products include geotextiles, geomembranes, geogrids, geocells, geosynthetic clay liners, and drainage boards, etc al. GEOSINCERE customers are from more than 1000 countries including America, Australia, France, Sweden, UK, Hong Kong, Hungary, New Zealand, Poland, Mexico, Ecuador, Brazil, Pakistan, Bangladesh, Thailand, Vietnam, Malaysia, Indonesia, Singapore, Philippines, Sri Lanka, India, UAE, Saudi Arabia, Qatar, Kenya, Ghana, Ethiopia, Somalia, Nigeria, South Africa, Swaziland, Mongolia, etc.

GEOSINCERE offers both high quality geosynthetic products but also professional design and installation service. OEM, ODM, custom development and fabrication are also available. If you have any questions or inquiries, please contact us, we will reply as soon as possible.