1. What is High Density Polyethylene Geomembrane?

Polyethylene geomembrane is a type of liner made from high-density polyethylene (HDPE) material that is used to contain liquids and prevent seepage. It is a flexible, durable, and impermeable material that is resistant to punctures, tears, and chemical corrosion. Polyethylene Geomembranes are commonly used in various industries, such as agriculture, mining, waste management, and water treatment, to provide a barrier against leakage and contamination. As the leading geosynthetics manufacturer and supplier, GEOSINCERE offer various types geomembrane with custom thickness and size at best factory price.

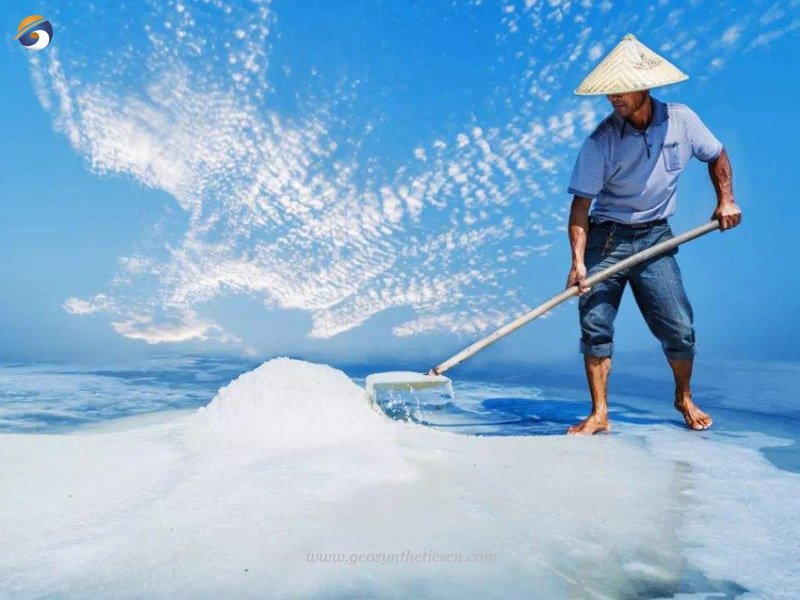

2 High Density Polyethylene Geomembrane for Salt Industry

In the salt industry, Polyethylene Geomembrane is used to line salt ponds and prevent seepage of saltwater into the surrounding soil and groundwater. This helps to protect the environment and preserve the quality of the salt production. The installation of Polyethylene Geomembrane involves laying a layer of non-woven geotextile on the compacted soil, followed by the Polyethylene Geomembrane layer, which is then welded together along the seams using a specialized machine for maximum integrity. Once the installation is complete, the entire surface area is protected with an additional layer of non-woven geotextile or a layer of soil cover to protect against UV radiation and potential puncturing.

3 What is The HDPE Geomembrane Specifications

Polyethylene Geomembranes are available in various thicknesses, ranging from 0.5mm to 3.0mm, depending on the specific application and the level of protection required. They are also available in different colors, such as black, white, and green, to meet different aesthetic and functional needs. Additionally, Polyethylene Geomembranes can be manufactured as food-grade materials, making them suitable for use in the food processing industry.

4 Applications of HDPE Geomembrane Indonesia

Indonesia has a thriving salt industry, where salt is traditionally produced by sun-drying. The tropical climate and abundant sunshine make it an ideal location for this industry. The process involves filling shallow pools with seawater and allowing the sun’s heat to evaporate the water, leaving behind salt crystals. The harvested salt is then washed, graded, and sold for various purposes, such as food processing, industrial use, and water treatment. This traditional method has been practiced for centuries and continues to be a significant source of income for local communities along the coastline.

The use of Polyethylene Geomembrane in the salt industry has several advantages. Firstly, HDPE smooth geomembrane is highly resistant to chemical corrosion, making it ideal for salt industry applications where salt can be highly corrosive to conventional materials. Secondly, Polyethylene Geomembrane has excellent tensile strength and puncture resistance, providing superior protection against leaks and environmental damage. Additionally, Polyethylene Geomembrane is lightweight, flexible, and easy to install, providing cost-effective and efficient solutions for the salt industry. Lastly, HDPE black anti-UV geomembrane is highly durable, providing a long service life and reducing maintenance costs over time.

5 Advantages of HDPE Geomembrane Liner

Polyethylene Geomembrane has several advantages, including high tensile strength and excellent elongation properties. It also has excellent chemical resistance, making it suitable for use in harsh environments. Additionally, it is impermeable to water and gases, making it an effective barrier against leaks and contamination. Polyethylene Geomembrane is also UV resistant and can withstand prolonged exposure to sunlight without degradation. Lastly, it is flexible and easy to install, allowing for contoured and complex designs in various applications.

Without the use of geomembranes, the salt industry may encounter several difficulties, including:

1. Soil erosion:

Salt fields are more prone to soil erosion due to heavy rain or wind, leading to a loss of soil nutrients and decreased yields.

2. Soil salinization:

Salt can easily penetrate into the soil, leading to soil salinization, which can negatively impact plant growth and yield.

3. Water waste:

When salt is spread directly on the ground, it can easily dissolve in water and be carried away, resulting in water waste and potential contamination of nearby water sources.

4. Increased maintenance costs:

Salt fields may require more frequent maintenance to control weeds and pests, leading to increased labor and equipment costs.

5. Environmental impact:

Salt runoff and soil erosion can have negative environmental impacts, including damage to nearby ecosystems and wildlife habitats.

A famous local salt factory in Indonesia requested a sample of our geomembrane and conducted tests, finding that our geomembrane, GEOSINCERE’s geomembrane, not only has excellent performance but is also food-grade. After negotiations and price discussions, they purchased our 1.0mm geomembrane liner. To protect the geomembrane from damage, we also provided them with 200g PET geotextiles for protection. We will also visit the customer regularly to monitor the use of the geomembrane.

6 Specification of the Polyethylene Geomembrane used for the salt industry in Indonesia

– Product Name: 1.0mm HDPE ployethylene geomembrane

– Roll Size: 7m x 100m

– Quantity: 300,000 square meters.