A geotextile is typically defined as any permeable textile material used to increase soil stability, provide erosion control or aid in drainage. Geotextiles can be categoried as non woven geotextile and woven geotextiles. Non woven geotextiles are usually made from a synthetic polymer such as polypropylene, polyester, polyethylene and polyamides. Varying polymers and manufacturing processes result in an array of geotextiles suitable for a variety of civil construction applications.

Non-woven geotextiles resemble felt and provide planar water flow. They are commonly known as filter fabrics, although woven monofilament geotextiles can also be referred to as filter fabrics. Typical applications for non-woven geotextiles include aggregate drains, asphalt pavement overlays and erosion control. Nonwoven fabrics can be made of either polyester or polypropylene . Nonwoven filter fabrics are used as separation fabrics when higher water flow is required for the application. This can include acting as a separator between the drainage gravel backfill behind a retaining wall, wrapping the stone surrounding the pipe in a french drain, or as an underlayment below riprap. Nonwoven fabrics can also be treated to resist water flow and used as a pavement underlay by binding with the asphalt to create a barrier to water.

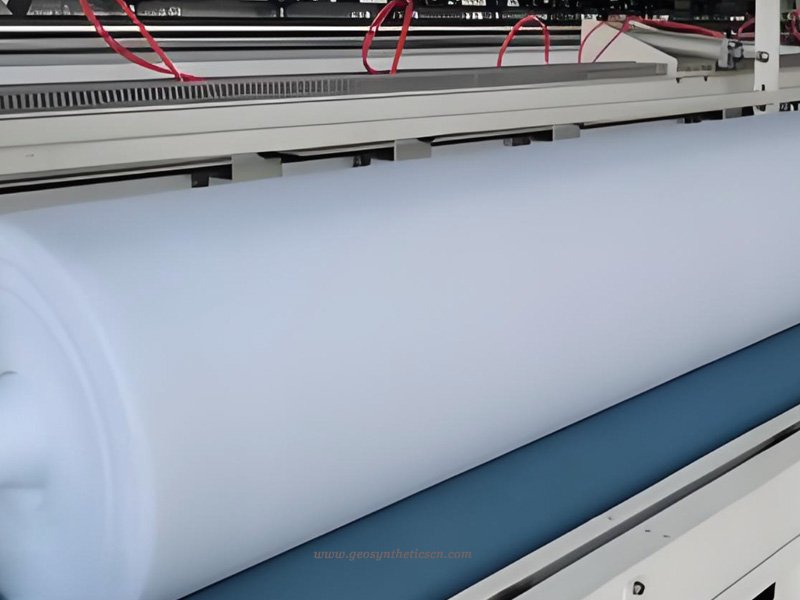

As the leading geosynthetics manufacturer, GEOSINCERE offers a wide range of woven and nonwoven geotextile at best factory price. In this article, we specifically introduce the nonwoven geotextile.

1. What Are Functionsof Nonwoven Geotextile?

Nonwoven Geotextiles are used in a wide range of civil engineering and construction applications, including:

1.1 Separation

Nonwoven Geotextiles are placed between different soil layers or between soil and other materials (such as aggregate or geomembranes) to prevent mixing and maintain the integrity of the layers. This helps prevent the loss of structural integrity due to intermixing of materials and reduces the risk of settlement.

1.2 Filtration

Nonwoven Geotextiles act as filters to allow the passage of water while retaining soil particles. They are used to prevent the clogging of drainage systems, such as French drains or geocomposite drains, by filtering out fine particles and preventing soil migration.

1.3 Drainage

Nonwoven Geotextiles with high permeability allow water to pass through while preventing the movement of soil particles. They are used in drainage applications to facilitate the flow of water away from structures, roads, or other areas susceptible to water accumulation.

1.4 Reinforcement

Nonwoven Geotextiles can be used to reinforce soil structures, such as retaining walls, embankments, and slopes, by distributing loads and reducing the risk of soil erosion and failure. They improve the stability and strength of soil structures, particularly in areas with poor soil conditions or high traffic loads.

1.5 Erosion Control

Nonwoven Geotextiles help stabilize soil surfaces and prevent erosion by protecting against surface runoff, wave action, and wind erosion. They are used in applications such as slope stabilization, shoreline protection, and revegetation projects to mitigate the effects of erosion and maintain soil stability.

2. What Is Non Woven Geotextile Used For?

Nonwoven geotextiles find versatile applications across various industries due to their exceptional durability and performance characteristics. Some common uses of nonwoven geotextiles, including GEOSINCERE NONWOVEN GEOTEXTILE, are:

2.1 Drainage

Nonwoven geotextiles are utilized to facilitate effective drainage systems by providing filtration and separation in soil layers.

2.2 Pipe Wrap

Non woven geotextiles is employed for wrapping pipes to protect them from abrasion, corrosion, and other forms of damage.

2.3 Filter Fabric

Non woven geotextile acts as filter fabrics to prevent soil erosion, promote drainage, and retain soil particles.

2.4 Landscape Fabric

Non woven geotextiles is used in landscaping projects to control weed growth, promote soil stabilization, and enhance the overall aesthetics of the area.

2.5 Weed Barrier

Nonwoven geotextiles serve as effective weed barriers in gardens, agriculture, and landscaping to inhibit weed growth and maintain the health of plants.

6. **Railroad Ballast Separation:** They are applied in railway construction to separate and stabilize the ballast layers, improving the overall performance and longevity of the railroad infrastructure.

These applications highlight the versatility and effectiveness of nonwoven geotextiles in various construction, civil engineering, landscaping, and agricultural projects where filtration, separation, reinforcement, and protection are essential.

3. What Are Categories of Non Woven Geotextile?

Non woven geotextile can be categorized based on various factors, including manufacturing process, material composition, application, and performance characteristics. Here are some common categories of nonwoven geotextiles:

3.1 Needle Punched Nonwoven Geotextiles

These geotextiles are manufactured using a needle-punching process, where synthetic fibers are mechanically entangled and interlocked to form a cohesive fabric structure. Needle-punched geotextiles are known for their high strength, durability, and puncture resistance, making them suitable for applications requiring robust performance, such as separation, filtration, and reinforcement.This is the most common use geotextile.

3.2 Thermal Bonded Nonwoven Geotextiles

Thermal-bonded geotextiles are produced by heating and melting synthetic fibers to bond them together, forming a stable fabric structure without the use of adhesives or mechanical entanglement. Thermal-bonded geotextiles exhibit uniformity, smoothness, and excellent filtration properties, making them ideal for applications such as drainage, erosion control, and protection of geomembranes.

3.3 Spunbonded Nonwoven Geotextiles

Spunbonded geotextiles are manufactured using a continuous extrusion process, where synthetic fibers are spun and laid down onto a conveyor belt to form a web. The web is then bonded together using heat and pressure to create a strong and durable fabric. Spunbonded geotextiles offer high tensile strength, flexibility, and resistance to UV degradation, making them suitable for various civil engineering and construction applications, including reinforcement, separation, and filtration.

3.4 Meltblown Nonwoven Geotextiles

Meltblown geotextiles are produced by extruding molten polymer through fine nozzles to create microfibers, which are then randomly deposited onto a conveyor belt to form a porous web. The web is then bonded together using heat or pressure to create a cohesive fabric structure. Meltblown geotextiles exhibit excellent filtration properties, making them ideal for applications such as drainage, erosion control, and filtration of fine particles.

3.5 Composite Nonwoven Geotextiles

Composite geotextiles consist of multiple layers of different nonwoven geotextile fabrics or other geosynthetic materials bonded together to form a single integrated product. Composite geotextiles combine the beneficial properties of different materials to achieve specific performance requirements, such as enhanced filtration, drainage, or reinforcement.

3.6 Biodegradable Nonwoven Geotextiles

Biodegradable geotextiles are manufactured using natural or synthetic fibers that are designed to degrade over time when exposed to environmental conditions such as sunlight, moisture, and microbial activity. Biodegradable geotextiles offer environmentally friendly solutions for erosion control, revegetation, and temporary applications where long-term stability is not required.

The weights of non woven geotextile we offer range from light weight to heavy weight. They include:

- 3.1 oz non woven geotextile fabric

- 3.5 oz non woven geotextile fabric

- 4 oz non woven geotextile fabric

- 4.5 oz non woven geotextile fabric

- 6 oz non woven geotextile fabric

- 8 oz non woven geotextile fabric

- 10 oz non woven geotextile fabric

- 12 oz non woven geotextile fabric

- 16 oz non woven geotextile fabric

4. What Are Benefits of Nonwoven Geotextile?

If you’re looking for a synthetic fabric that is environmentally friendly and will last a longer time, GEOSINCERE nonwoven geotextile fabrics are a great option for all industrial applications. It has below benefits:

While woven geotextile fabrics can come apart, this is generally not a concern with nonwoven fabrics since there are no individual threads that can separate.

Nonwoven geotextile fabrics are sometimes more affordable than woven ones.

Nonwoven fabrics tend to be quite durable, and this makes them perfect for a variety of outdoor projects. As a result, they’re great for people who are doing projects in their backyard or for commercial landscaping and flood control.

Nonwoven geotextile fabrics have excellent filtration properties, a high level of tensile strength, and the layers make needle punching easy. Furthermore, polypropylene nonwoven geotextile products are known for their exceptional durability.

5. Woven vs. Nonwoven Geotextiles

Woven textiles contain singular threads, which are woven together. This can be done by hand or with machinery. However, nonwoven textiles do not have threads woven together at all, but they are instead combined with a chemical or mechanical process. Here are a few examples of techniques that are used to create non woven fabrics:

Chemical means of fusing the fabric together: There are a variety of chemicals that can be used to fuse fabrics together without weaving. These chemicals are widely used in the textile industry, and this includes companies that work with geotextiles.

Mechanical techniques to fuse the fabric together: There are multiple other methods that can be used for fusing nonwoven geotextile fabrics together. Some examples of these techniques are the use of high levels of heat and attaching pieces of foam-like materials with adhesives.

6. Summary

To sum up, nonwoven geotextiles offer a combination of properties that make them versatile and effective solutions for a wide range of civil engineering, construction, and environmental applications. These properties enable nonwoven geotextiles to provide essential functions such as filtration, separation, drainage, reinforcement, and erosion control, contributing to the durability, stability, and sustainability of infrastructure systems and environmental protection measures.

GEOSINCERE has been dedicated to manufacturing wholesaling geotexitle and geosynthetics products and solutions to worldwide customers since its foundation in 2007. If you have any questions or inquiries, please contact us, we will reply as soon as possible.