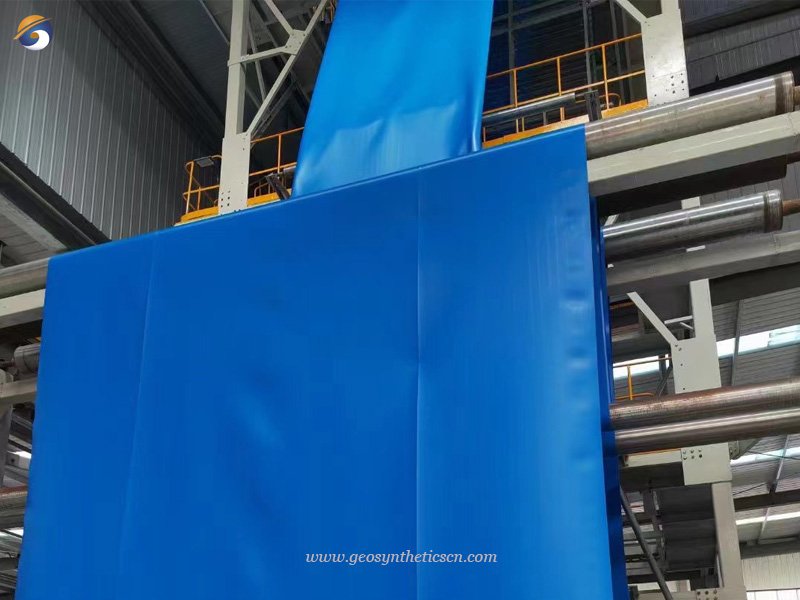

HDPE pond membrane liner, also known as HDPE geomembrane liner, is produced from high-density polyethylene resin. The manufacturing process involves film-blowing, adding carbon black, antioxidant, anti-aging, and UV-resistance components to form a sheet. Smooth ponf membrane liner is the low permeable synthetic membrane liner and geotechnical engineering materials which are widely used for aquaculture, solid waste containment, mining and water containment applications.

1. What Is Pond Membrane Liner?

Pond membrane liners are impermeable barriers designed to line the bottom and/or sides of ponds, reservoirs, or other water containment structures. They play a vital role in preventing water from seeping into the surrounding soil, ensuring that the water remains within the intended area. This helps maintain water levels, prevent contamination, and safeguard the environment.

Material Selection

The selection of a suitable pond membrane liner depends on various factors, including the size and shape of the pond, the type of soil, and the intended use. Different materials are available, each offering specific advantages. For instance, EPDM liners are known for their durability and flexibility, making them suitable for various climates. HDPE liners, on the other hand, are valued for their strength and puncture resistance, making them a popular choice for commercial applications and larger ponds. PVC liners are lightweight, flexible, and cost-effective, often used in smaller ponds. RPE liners, reinforced polyethylene, provide enhanced puncture resistance, making them ideal for commercial applications or areas prone to potential damage.

During Installation

Proper site preparation is crucial. It involves clearing the area of sharp objects and debris that could puncture the liner. Additionally, seam welding or seaming techniques should be used to create a watertight seal between liner sections, minimizing the risk of leaks and seepage.

To ensure optimal performance and longevity of the liner, it is advisable to consult professionals experienced in pond liner installation and adhere to manufacturer guidelines.

GEOSINCERE

If you have specific questions or need advice on pond membrane liners for your project, please provide more details, and I’ll be happy to assist you further. Our company also offers a range of high-quality HDPE geomembrane pond liner products, including smooth membrane pond liners, textured HDPE pond liners, and composite geomembrane liners. These innovative products are ideal for environmental, civil, and industrial applications. Our HDPE geomembranes have obtained certifications such as ISO9001, ISO14001, TUV, Soncap, SASO, BV, and have been tested by reputable organizations like SGS and Intertek.

2. What Are Advantages of HDPE Pond Membrane Liner?

The HDPE pond membrane liner offers several notable features that make it a reliable choice for water containment structures:

2.1 Excellent chemical resistance:

HDPE liners are highly resistant to various chemicals, ensuring the integrity and safety of the water containment system.

2.2 Outstanding stress crack capacity:

HDPE liners have exceptional resistance to stress cracks, making them highly durable and less prone to damage.

2.3 Lowest permeability, excellent UV resistance:

HDPE liners have very low permeability, minimizing water seepage and ensuring water remains within the designated area. They also exhibit excellent resistance to UV radiation, protecting the liner from degradation caused by sunlight exposure.

2.4 Stable low-temperature embrittlement resistance:

HDPE liners maintain their flexibility and performance even in low-temperature environments, preventing brittleness and ensuring their effectiveness in different climates.

2.5 Complete width and thickness specifications:

HDPE liners are available in a wide range of widths and thicknesses, allowing for customization based on specific project requirements.

2.6 Proven performance:

HDPE liners have a track record of successful use in various water containment applications, demonstrating their reliability and effectiveness.

2.7 Meets or exceeds GRI GM13 standards:

GRI GM13 is a guideline established by the Geosynthetic Institute for geomembrane liners. HDPE pond membrane liners meet or exceed the requirements specified by this standard, ensuring their quality and performance.

These features collectively make HDPE pond membrane liners a popular choice for commercial, environmental, and industrial applications where reliable water containment is critical.

3. Case Study of HDPE Pond Membrane Liner for Shrimp Pond Project in Colombia

4. How To Install HDPE Pond Membrane Liner

Before applying impermeable membrane liner, the slope surface should be leveled to prevent sharp outburst, and then the loose soil should be covered with HDPE membrane pond liner.

-

Installation Considerations:

- The liner should be extended from the bottom to the high position with a 1.50% margin for sinking and stretching.

- The slope should be laid from top to bottom.

- Adjacent longitudinal joints should be staggered by more than 1m.

- Longitudinal joints should be at least 1.50m away from the dam foot and bending foot and set on the plane.

-

Slope Installation:

- Inspect and measure the laying area before installation.

- Transport the HDPE liner with matching size to the anchorage ditch platform.

- “Push” the liner from top to bottom according to the site conditions.

- Cut the liner reasonably in the sector area and ensure proper anchoring.

-

Bottom Installation:

- Inspect and measure the laying area before installation.

- Transport the HDPE liner with matching size to the corresponding position.

- Manually push the liner in a certain direction during installation.

-

Alignment:

- Ensure the HDPE liner is flat and straight to avoid wrinkles and ripples.

- Align and align the two geomembranes.

- Maintain a lap width of about 10 cm as per design requirements.

-

Pressing:

- Use sandbags to press the aligned HDPE liner to prevent wind displacement.

-

Anchorage Ditch Laying:

- Reserve a sufficient amount of HDPE liner at the top of the anchorage ditch for sinking and stretching.

-

Longitudinal Joint:

- Place the uphill section on the upper side and the downhill section on the lower side.

- Ensure a lap length of ≥ 15 cm.

- Lay a bentonite pad in the accepted area and carry out manual “push paving” in a specific direction.

5. About GEOSINCERE

As the professional geotextile and geosynthetics manufacturer and wholesaler, GEOSINCERE is always committed to geotextile research and development, manufacturing and installation services. We can provide our customers with most extensive lines of geotextiles and geomembranes for civil, mining, environmental and aquaculture engineering applications.

Our main innovative, high quality products include geotextiles, geomembranes, geogrids, geocells, geosynthetic clay Liner, and drainage boards, etc al.

GEOSINCERE offers both high quality geosynthetic products but also professional design and installation service. OEM, ODM, custom development and fabrication are also available. If you have any questions or inquiries, please contact us, we will reply as soon as possible.