HDPE waterproofing membrane, also known as HDPE geomembrane liner, is the kind of cost effective and ideal anti seepage lining geosynthetic material widely used for waste containment, water containment, aquaculture, industrial project, energy project and mining project, etc. HDPE waterproofing membrane is composed of specially formulated HDPE resin and specific amount of carbon black, anti-aging agent and anti-ultraviolet component.

Features Of HDPE Waterproofing Membrane

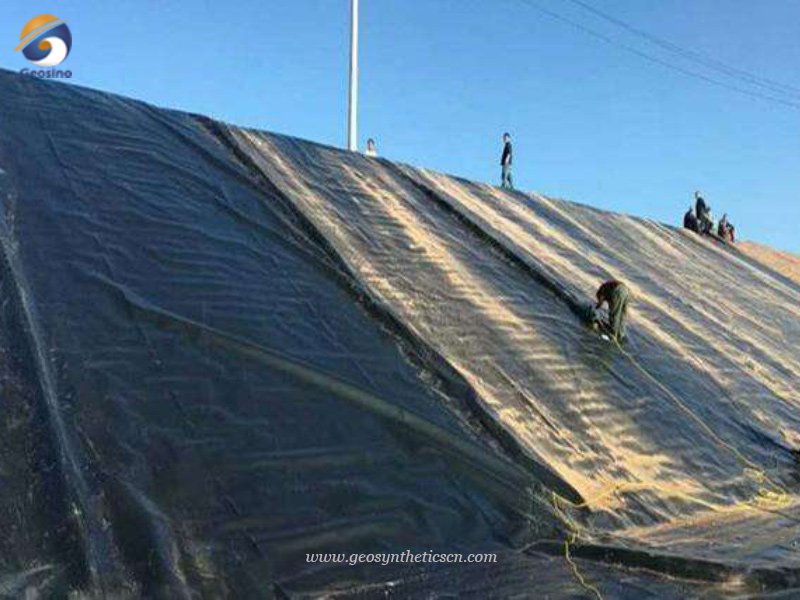

The iron ore tailings impermeable membrane has excellent impermeability, anti-leakage and moisture resistance. Compared with traditional concrete, asphalt and compacted clay, it is more cost-effective, environmentally safe, durable, chemical resistant, quick to deploy and easy to transport. HDPE waterproofing membrane is used as a barrier for slag and waste water in the treatment of iron ore tailings. It is widely used in iron ore tailings construction and environmental protection treatment due to its high tensile strength, anti-aging and corrosion resistance, and good anti-seepage effect.

HDPE Membranes in Mining Waste Management

The mining industry produces much solid waste, especially waste rock and tailings. HDPE geomembranes retain chemical solutions for ore processing and collect leachate. Iron ore tailings result from the beneficiation process, leaving behind slag. Globally, there are over 400,000 mines with more than 10 billion tons of stockpiled tailings. Annual tailings discharge exceeds 5 billion tons, with ferrous mines discharging 500 million tons. Accumulated tailings harm the environment and waste valuable resources. Using HDPE membranes in tailings projects saves arable land and protects vegetation. These membranes reduce the impact of tailings ponds on land use and environmental damage. They prevent harmful substances from entering ecosystems, preserving vegetation and water quality. Overall, HDPE membranes improve resource reuse and environmental protection in mining areas.

Impacts of Improper Iron Ore Tailings Management

The stacking of iron ore slag harms natural scenery and tourism.Enhancing tailings recycling can boost the economy and protect the environment.Improper iron ore and tailings management harms ecology and people. This is mainly manifested in:

- Building tailings ponds uses arable land and harms surrounding vegetation.This worsens the conflict between population growth and shrinking land resources.

- Residual flotation reagent ions in iron ore tailings contaminate rainwater.This pollution affects fields and rivers, harming the environment.

- Harmless tailings components transform in nature. They break down, sparking reactions. Soluble ions from these processes pollute the environment.

- Long-term tailings stacking poses geological risks. Tailings’ fine particles stir sandstorms in dry spells. These storms degrade nearby ecosystems, harm crops, trigger respiratory ailments.

Case Study Of HDPE Waterproofing Membrane

GEOSINCERE’s Indonesian client won an iron ore tailings project through a tender in April 2021. The project requires iron ore tailings anti-seepage membrane for construction. This customer asked us about 68,000 square meters of iron ore tailings anti-seepage membrane products. In order to learn more about the anti-seepage performance of our products, he came to our factory and finally confirmed the quality of the geomembrane and signed a contract with us. . More importantly, our construction technicians introduced in detail how to use and how to install iron ore tailings impermeable membrane. At the same time, the Yunnan customer paid the deposit and confirmed the delivery schedule.

Specifications of HDPE Waterproofing Membrane for Iron Ore tailings Treatment Projects in Indonesia

- HDPE Waterproof Membrane Thickness – 1.5mm

- Each Roll Size – 6m*50m

- Total Quantity – 68000 Square Meters

About GEOSINCERE

As the professional geotextile and geosynthetics manufacturer and wholesaler, GEOSINCERE is always committed to geotextile research and development, manufacturing and installation services. We can provide our customers with most extensive lines of geotextiles and geomembranes for civil, mining, environmental and aquaculture engineering applications. GEOSINCERE has been keeping on investing in technological innovation, manufacturing facilities improvement and turnkey engineering abilities. Our extensive lines of geosynthetics products are well known for their ensured quality, high performance, excellent durability and best cost effectiveness. GEOSINCERE brand geotextiles and other geosynthetics products and solutions can meet your requirements by our solid technologies, innovative engineering solutions and excellent customer services. Hope to be your partner.

Our main innovative, high quality products include geotextiles, geomembranes, geogrids, geocells, geosynthetic clay Liner, and drainage boards, etc al. GEOSINCERE customers are from more than 100 countries.

GEOSINCERE offers both high quality geosynthetic products but also professional design and installation service. OEM, ODM, custom development and fabrication are also available. If you have any questions or inquiries, please fill and submit the following form, we will reply as soon as possible.