Description

Fiberglass geogrid, also known as glass fiber geogrid, is specially designed and manufactured to largely increase the bearing capacity and prolongs the performance of the asphalt pavement, soft soil road, cement road, concrete road, etc. BPM Geosynthetics is one of the largest geogrid manufacturers and suppliers with 14+ years experiences, we offer high qaulity geogrid for sale at competitive factory price. In addition, we also supply plastic or PP geogrids.

1. What Is Fiberglass Geogrid?

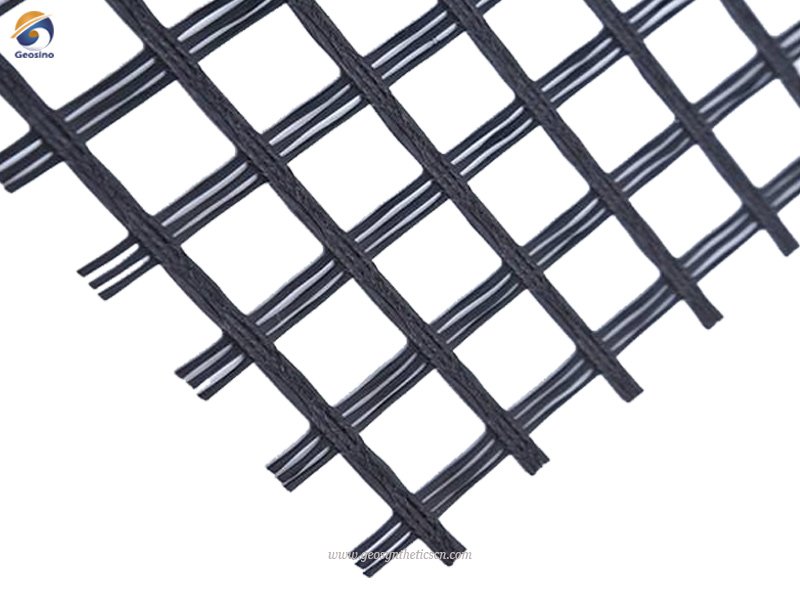

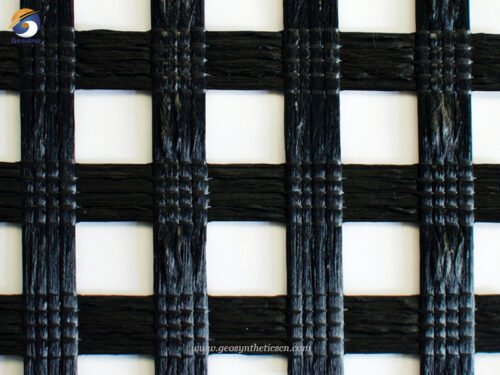

Fiberglass geogrid is a type of geosynthetic material used in geotechnical engineering applications. It is made by weaving fiberglass filaments together to create a grid-like structure. The woven pattern forms a strong and flexible fabric that offers reinforcement and stabilization to soil and other materials.

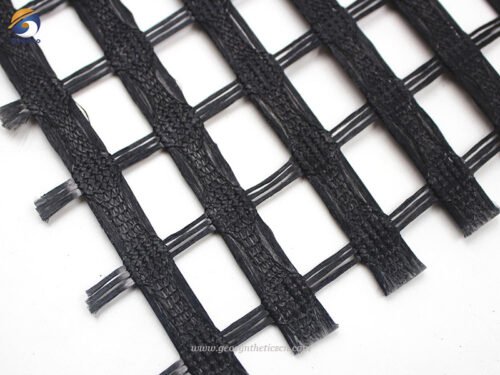

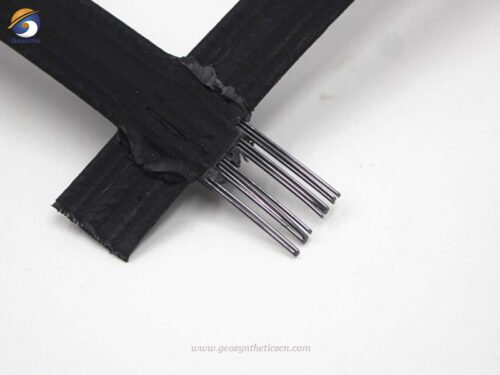

The fiberglass filaments used in geogrids are typically made from high-strength, corrosion-resistant fiberglass materials. These filaments are woven or knitted together to form a grid pattern, creating a stable and durable fabric. The resulting geogrid fabric exhibits excellent tensile strength, allowing it to distribute loads and provide reinforcement to the soil. Fiberglass geogrid fabric is made of fiberglass yarns coated with a polymer resin. The yarns are then woven or knitted into a grid-like pattern.

Fiberglass geogrid is manufactured from excellent non-alkali fiberglass filament as the base material uniquely coated with adhesive by automatic woven technology. The aperture size of glass fiber geogrid ranges are available for optimum matching with most material filling which leads to the reduction in differential settlement and improved foundation bearing capacity.

Fiberglass geogrid can make full use of yarn textile strength and warp knitting directional structure to improve its high tensile strength, excellent tensile modulus, good wear resistance and creep resistance, and excellent thermal stability, etc. Fiberglass has the characteristics of very low shrinkage and ultimate elongation, good creep resistance, excellent heat resistance and stability, excellent UV stabilization, chemical and biological resistance, and stable low temperature embrittlement resistance, etc.

2. Fiberglass Geogrid Specifications

| Item |

GSB30-30

|

GSB40-40

|

GSB50-50 |

GSB80-80 |

GSB100-100 |

GSB125-125 |

GSB150-150 |

| Size of mesh (mm) |

12.7*12.7~25.4*25.4 |

| Tensile Strength (kN/m) |

Longitudinal |

≥30 |

≥40 |

≥50 |

≥80 |

≥100 |

≥125 |

≥150 |

| Transverse |

≥30 |

≥40 |

≥50 |

≥80 |

≥100 |

≥125 |

≥150 |

| Elongation Rate (%) |

≤4 |

| Temperature Resistance (℃) |

100~280 |

3. What Are Features of Fiberglass Geogrid Fabric?

Fiberglass geogrid fabric is the reliable and efficient material for soil reinforcement and stabilization in geotechnical applications. Its strength, resistance to temperature and aging, and cost-effectiveness contribute to its widespread use in various engineering projects.

3.1 Good Heat Resistance

Fiberglass geogrid exhibits excellent heat resistance, allowing it to maintain its structural integrity and performance even under high temperatures. This characteristic makes it suitable for applications in hot climates or where temperature fluctuations are significant.

3.2 High Tensile Strength

Fiberglass geogrid possesses several notable features, including:

- Good Heat Resistance. Fiberglass geogrid exhibits excellent heat resistance, allowing it to maintain its structural integrity and performance even under high temperatures. This characteristic makes it suitable for applications in hot climates or where temperature fluctuations are significant.

- High Tensile Strength. Fiberglass geogrids have high tensile strength in both the warp and weft directions. This means they can withstand substantial forces and distribute loads effectively, providing reinforcement and stability to soil structures.

3.3 Low Elongation

The elongation of fiberglass geogrids is minimal, meaning they have low deformation under load. This quality ensures that the geogrids maintain their shape and stability even when subjected to heavy loads or stress.

3.4 Excellent Temperature Range

Fiberglass geogrids offer a wide temperature range within which they can perform effectively. They can withstand both hot and cold temperatures without significant loss of strength or deformation.

3.5 Good Anti-Aging and Alkali-Resistance

Fiberglass geogrids are resistant to aging processes, ensuring their long-term durability. They also exhibit good resistance to alkali, which is beneficial in applications where the geogrids may come into contact with alkaline substances.

3.6 Nesting, Interlock, and Restraint Effects

The grid-like structure of fiberglass geogrids allows for nesting, interlocking, and restraint effects when placed within the soil or other materials. This enhances their ability to distribute loads and provide stability, improving the overall performance of the geotechnical system.

3.7 Cost Effectiveness

Fiberglass geogrids offer a cost-effective solution for various applications. Their durability and long lifespan contribute to cost savings over the entire life cycle of the pavement or soil structure.

3.8 Suitable for Asphalt Mixes

Fiberglass geogrids are especially suitable for use in asphalt mixes. They can reduce the required thickness of aggregate layers, resulting in cost savings and improved pavement performance.

4. What Are the Applications of Fiberglass Geogrid?

GEOSINCERE fiberglass geogrids are designed to provide reinforcement and stabilization to soil, making them suitable for various in various civil engineering and construction projects. Some of the key applications include:

- Road Construction: Fiberglass geogrids are commonly used in road construction projects. They provide reinforcement and stabilization to the roadbed, enhancing its load-bearing capacity and preventing deformations. They are used in both new road constructions and maintenance or repair jobs to improve the pavement life.

- Asphalt Pavement Reinforcement: Fiberglass geogrids are employed in asphalt pavements to enhance their durability and resistance to rutting. They are particularly useful in high-traffic areas or locations prone to intensive vehicle braking or accelerating. By distributing the stresses and preventing the formation of ruts, the geogrids help maintain the integrity of the pavement.

- Concrete Pavement Reinforcement: Fiberglass geogrids are utilized in the construction of concrete pavements to reinforce the structure and prevent cracking. They are effective in controlling reflective cracking, which occurs due to the movement of underlying layers or joints. The geogrids help distribute the stresses and minimize the propagation of cracks.

- Airport Runways and Taxiways: Fiberglass geogrids are used in the reinforcement and crack prevention of airport runways, taxiways, and aprons. These areas experience heavy loads and require enhanced stability. The geogrids help control reflective cracking and improve the longevity of the pavement.

- Bridges and Parking Lots: Fiberglass geogrids are applied in the construction of roads, bridges, and parking lots to enhance their strength and prevent cracking. They provide reinforcement to the concrete or asphalt layers, improving their resistance to deformation and extending their service life.

- Jointed Concrete Highways: Fiberglass geogrids are employed in jointed concrete highways to control reflective cracking. By reducing the propagation of cracks from joints, the geogrids help maintain the integrity and smoothness of the highway surface.

5. When Should You Use Glass Fiber Geogrid?

It is generally recommended to use fiber glass geogrid for walls taller than three to four feet. However, even shorter walls may require geogrid if there are steep slopes nearby, if there is loading above the wall, if the walls are tiered, or if the soils are poor.

Fiber glass geogrid is a crucial component in various hardscape projects, including driveways, walkways, patios, and more. When it comes to retaining walls, especially those exceeding three or four feet in height, geogrid becomes even more essential. It is better to err on the side of caution and install geogrid, even if it may not seem immediately necessary, as it provides added stability and reduces the risk of future wall failure. Investing in geogrid installation ensures the long-term durability and reliability of the wall structure.

6. Where Do You Put a Glass Fiber Geogrid?

When installing a glass fiber geogrid, it is typically rolled out and placed in specific locations to provide reinforcement and stability. The geogrid should be laid out following the natural contours of the ground. The design documents will usually provide instructions regarding the recommended direction of laying and vertical spacing of multiple layers.

GEOSINCERE, a specific brand or product, can be placed on the subgrade, which refers to the natural ground surface. It can be positioned either parallel to a road centerline or at right angles to it, depending on the project requirements. Proper placement of the geogrid is crucial to ensure its effectiveness in enhancing soil reinforcement and preventing soil movement or settlement. It is advisable to consult the design documents and, if necessary, seek guidance from a geotechnical engineer for the specific installation instructions related to the glass fiber geogrid being used.

7. About GEOSINCERE

GEOSINCERE has been dedicated to manufacturing wholesaling geotexitle and geosynthetics products and solutions to worldwide customers since its foundation in 2007. Our main innovative, high quality products include geotextiles, geomembranes, geogrids, geocells, geosynthetic clay liners, and drainage boards, etc al.

GEOSINCERE customers are from more than 1000 countries including America, Australia, France, Sweden, UK, Hong Kong, Hungary, New Zealand, Poland, Mexico, Ecuador, Brazil, Pakistan, Bangladesh, Thailand, Vietnam, Malaysia, Indonesia, Singapore, Philippines, Sri Lanka, India, UAE, Saudi Arabia, Qatar, Kenya, Ghana, Ethiopia, Somalia, Nigeria, South Africa, Swaziland, Mongolia, etc.

GEOSINCERE offers both high quality geosynthetic products but also professional design and installation service. OEM, ODM, custom development and fabrication are also available. If you have any questions or inquiries, please contact us, we will reply as soon as possible.