Description

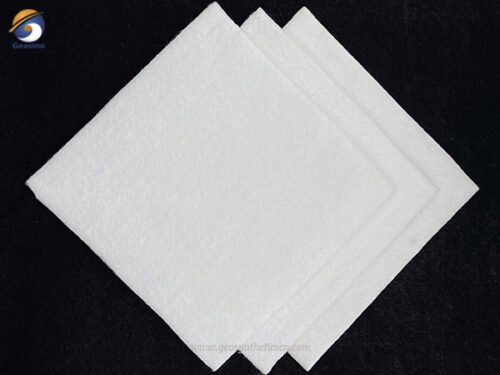

PET woven geotextile is the woven geo fabric made from high tenacity which is used to provide stability and limit differential settlement when constructing road. GEOSINCERE PET are engineered woven geotextiles fabricated with high tenacity and high molecular weight polyester (PET) yarns.

1. What Is PET Woven Geotextile?

PET woven geotextile is a durable and strong fabric made from polyester (PET) fibers that are woven together. It is commonly used in civil engineering and construction projects for various applications such as reinforcement, separation, filtration, drainage, and erosion control.

The manufacturing process of PET woven geotextile involves weaving high tensile and high molecular weight polyethylene terephthalate (PET) yarns together. This creates a fabric with excellent mechanical properties, including high tensile strength and dimensional stability. PET is known for its thermal stability, chemical resistance, and resistance to disintegration against strong alkalis and high temperatures.

GEOSINCERE PET woven geotextile is particularly notable for its remarkable ultimate tensile strength, which can reach up to 1200 kN/m in uniaxial directions. This makes it a cost-effective solution for reinforcement and stabilization applications in construction projects that require both high-strength reinforcement and separation functions.

PET woven geotextile provides reliable reinforcement to enhance the stability and performance of various structures. It effectively separates different soil layers, filters fine particles, and withstands challenging environmental conditions, ensuring long-lasting durability and performance. Its strength and chemical resistance make it suitable for a wide range of geotechnical applications, including road construction, slope stabilization, embankment reinforcement, and erosion control.

GEOSINCERE PET woven geotextile can benefit from a robust and cost-effective geotextile fabric that meets the demanding requirements of reinforcement and stabilization. It offers excellent performance, longevity, and reliability in geotechnical applications, contributing to the overall success and durability of the project.

2. Technical Data of Pet Woven Geotextile

| Property |

Unit |

GSO100-50 |

GSO300-50 |

GSO500-50 |

GSO600-50 |

GSO1200-50 |

| Ultimate Tensile Strength MD |

KN/m |

100 |

300 |

500 |

600 |

1200 |

| Ultimate Tensile Strength CD |

KN/m |

50 |

50 |

50 |

50 |

50 |

| Strain at short term strength |

% |

10 |

12 |

12 |

12 |

12 |

| Elongation |

% |

30 |

30 |

30 |

30 |

30 |

| Apparent Opening Size |

mm |

0.15 |

0.15 |

0.15 |

0.15 |

0.15 |

| UV resistance ( Retained 500 Hours) |

% |

70 |

70 |

70 |

70 |

70 |

| Width |

m |

5.2 |

5.2 |

5.2 |

5.2 |

5.2 |

| Height |

m |

100 |

100 |

100 |

100 |

75 |

| Roll weight |

Kg |

140 |

320 |

480 |

580 |

810 |

3. What Are Advantages of PET Woven Geotextile

PET woven geotextile offers several advantages that make it a preferred choice for various stabilization and reinforcement applications. Some of the key advantages of PET woven geotextile include:

3.1 High Tensile Strength

PET woven geotextile has excellent tensile strength, allowing it to provide strong reinforcement and stability to different structures. This ensures long-lasting performance and durability.

3.2 Good Tear Strength

The fabric’s tear strength is also noteworthy, as it helps resist tearing and damage during installation or in challenging environmental conditions.

3.3 Excellent CBR Value

CBR (California Bearing Ratio) value measures the strength of a material against penetration from a standard plunger. PET woven geotextile exhibits an excellent CBR value, indicating its ability to withstand heavy loads and distribute them effectively.

3.4 Good Resistance to Mineral Acids

PET woven geotextile demonstrates good resistance to mineral acids, making it suitable for applications where exposure to acidic environments is expected.

3.5 Good Resistance to Weak Alkalis

The geotextile also shows good resistance to weak alkalis, ensuring its stability and performance in alkaline conditions.

3.6 Disintegrates to Strong Alkalis and High Temperatures

PET woven geotextile disintegrates when exposed to strong alkalis and high temperatures, preventing the material from being damaged by these harsh conditions.

3.7 High Permittivity and Water Flow Rates

The geotextile’s high permittivity allows for efficient water flow and drainage, preventing water buildup and ensuring proper soil moisture balance.

3.8 Proven Performance for Stabilization and Reinforcement

PET woven geotextile has a track record of proven performance in various stabilization and reinforcement applications, making it a reliable choice for engineers and contractors.

3.9 Extensive Range of Size, Thickness, and Grades

PET woven geotextile is available in a wide range of sizes, thicknesses, and grades, allowing for customization and adaptation to different project requirements.

3.10 Ensured Quality, Factory Price, Fast Delivery

Manufacturers of PET woven geotextile ensure high-quality products, competitive factory pricing, and efficient delivery, providing convenience and reliability to construction projects.

PET woven geotextile offers numerous advantages, including strength, tear resistance, chemical resistance, water flow capabilities, proven performance, customization options, and reliable supply. These qualities make it a versatile and effective material for stabilization and reinforcement applications in civil engineering and construction projects.

4. What Is PET Woven Geotextile Used For?

In roadway and railway construction, PET woven geotextile is used for base reinforcement. It helps distribute the load and improve the stability of the base layers, reducing the risk of settlement and deformation.

4.1 Soil Stabilization

PET woven geotextile is employed in soil stabilization applications to enhance the strength and stability of weak soils. It prevents soil erosion, improves load-bearing capacity, and provides a stable platform for construction activities.

4.2 Slope Stabilization

PET woven geotextile is used to reinforce and stabilize slopes, preventing soil erosion, landslides, and slope failures. It helps to improve the shear strength of the soil and maintain slope integrity, ensuring long-term stability.

4.3 Embankment Protection and Reinforcement

PET woven geotextile is utilized to protect and reinforce embankments, such as those found in dams, levees, and riverbanks. It prevents soil erosion, provides stability to the embankment, and improves overall structural integrity.

4.4 Erosion Control

PET woven geotextile is effective in erosion control applications. It is used to prevent soil erosion on slopes, riverbanks, and shorelines by providing a protective layer that allows water to drain while retaining soil particles.

These are just a few examples of the many applications of PET woven geotextile. Its strength, durability, and resistance to environmental factors make it a versatile and reliable choice for various stabilization and reinforcement needs in civil engineering and construction projects.

5. About GEOSINCERE

GEOSINCERE has been dedicated to manufacturing wholesaling geotexitle and geosynthetics products and solutions to worldwide customers since its foundation in 2007. Our main innovative, high quality products include geotextiles, geomembranes, geogrids, geocells, geosynthetic clay liners, and drainage boards, etc. GEOSINO customers are from America, Australia, France, Sweden, UK, Hong Kong, Hungary, New Zealand, Poland, Mexico, Ecuador, Brazil, Pakistan, Bangladesh, Thailand, Vietnam, Malaysia, Indonesia, Singapore, Philippines, Sri Lanka, India, UAE, Saudi Arabia, Qatar, Kenya, Ghana, Ethiopia, Somalia, Nigeria, South Africa, Swaziland, Mongolia, etc.

GEOSINCERE offers both high quality geosynthetic products but also professional design and installation service. OEM, ODM, custom development and fabrication are also available. If you have any questions or inquiries, please contact us, we will reply as soon as possible.