Description

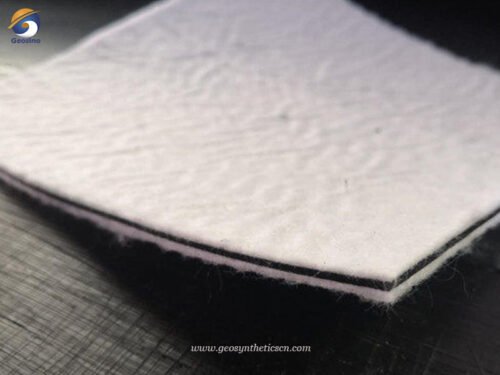

Textured Geomembrane liner has rough surface on either one or both sides which can highly improve the friction coefficient which fits more suitable for steep slope and vertical engineering design work which maximize the effective volume of geomembrane. As the leading geomembrane manufacturer and supplier, GEOSINCERE textured geomembrane is produced with approximately 97.5% virgin polyethylene, 2.5% carbon black and trace amounts of anti-oxidants and heat stabilizers by the automatic extrusion and spraying technology, the edges are also carefully processed smoothly to allow for high quality thermal fusion welding between adjacent connection. Textured geomembrane meets or exceeds the requirements of is ASTM D7466 – Standard Test Method for Measuring Asperity Height of Textured Geomembrane. This test method measures the height from the core membrane to the top of the texture peak.

Compared with smooth HDPE geomembrane, the textured HDPE geomembrane not only has the same features such as high tensile strength, tear resistance, puncture resistance, lowest permeability, alkali and acid resistance, also has superior shear strength, high multi-axial performance, excellent interface friction properties in combination with outstanding longevity. The textured surface processing is the only one that produces a textured material without significant reduction of any physical properties. The product allows project for greater slopes to be designed since frictional characteristics are enhanced. The textured geomembrane is suitable for such applications as retaining backfill on steep side slopes, landfill and pad baseline, heap leach pads, solid waste landfills, hazardous waste landfills, mining, coal ash pond, animal waste containment, etc.

GEOSINCERE provides high quality custom textured geomembrane with complete thickness, size and specifications at competitive factory price.

1. Textured Geomembrane Liner Specifications

| Test Properties |

Unit |

Standard |

Test frequency |

GSO10 |

GSO15 |

GSO20 |

GSO25 |

| Thickness |

mm |

D5994 |

per roll |

1.00 |

1.50 |

2.00 |

2.50 |

| Asperity Height |

mm |

D7446 |

Every 2nd roll (2) |

0.25 |

| Density |

g/cc |

D1505/D792 |

90,000kg |

0.94 |

| Tensile Properties |

| Yield Strength |

KN/m |

D6693

Type IV |

9,000 kg |

15 |

22 |

29 |

37 |

| Break Strength |

KN/m |

10 |

16 |

21 |

26 |

| Yield Elongation |

% |

12 |

12 |

12 |

12 |

| Break Elongation |

% |

100 |

100 |

100 |

100 |

| Tear Resistance |

N |

D1004 |

20,000kg |

125 |

187 |

249 |

311 |

| Puncture Resistance |

N |

D4883 |

20,000kg |

267 |

400 |

534 |

667 |

| Stress Crack Resistance |

hr |

D5397(App) |

per GRI GM-10 |

300 hr |

| Carbon black content |

% |

D4218 |

9,000kg |

2.0-3.0% |

| Carbon black dispersion |

|

D5596 |

20,000kg |

For 10 different views: 9 in Categories 1 or 2 and 1 in Category 3

|

| Oxidative Induction Time |

| Standard OIT |

min |

D3895 |

90,000kg |

100 min |

| High pressure OIT |

D5885 |

90,000kg |

400 min |

| Oven Aging at 85°C retained after 90 days |

% |

D5721 |

per each formulation |

55% |

| Standard OIT |

|

D3895 |

80% |

| High pressure OIT |

|

D5885 |

80% |

| UV Resistance |

| High Pressure OIT – % retained after 1600 hrs |

% |

D5885 |

per each formulation |

50% |

| Roll Width |

m |

|

|

7 |

7 |

7 |

7 |

| Roll Length |

m |

|

|

210 |

140 |

105 |

70 |

| Size stability |

% |

|

|

2% |

2. What Are The Benefits of Texutred Geomembrane Liner

- Imported high quality raw HDPE material.

- ISO9001, ISO14001, OHSAS18001 certificated factory.

- Lowest permeability.

- Superior shear strength.

- High multi-axial performance.

- Excellent interface friction properties.

- Excellent chemical resistance.

- Outstanding stress crack capacity.

- Excellent UV resistance.

- Stable low temperature embrittlement resistance.

- Complete range with width and thickness.

- Meets or exceeds all aspects of GRI GM13.

- Cost effective, Factory price.

- Careful robust package.

- Easy transportation, fast deployment.

3. What is Textured Geomembrane Material?

Textured geomembrane material is primarily made from high-density polyethylene (HDPE) raw material. HDPE is a commonly used polymer that possesses excellent chemical resistance, durability, and flexibility, making it well-suited for geomembrane applications. The textured surface is created during the manufacturing process by imprinting patterns or textures onto the HDPE material.

This texturing enhances the geomembrane’s frictional properties and stability, allowing it to effectively prevent seepage and provide slope protection in various engineering projects. The use of relatively virgin HDPE raw material ensures that the textured geomembrane meets the necessary quality standards and provides reliable performance in environmental and civil engineering applications.

4. How Thick Is Textured Geomembrane Liner

Similar to smooth geomembrane, the industry standard textured geomembrane thickness is typically measured in millimeters (mm) or mils (thousandths of an inch). Common thicknesses range from 0.5 mm (20 mils) to 3.0 mm (120 mils) or more. The selection of the appropriate thickness depends on factors such as the type of containment, environmental conditions, and the level of protection required.

5. Textured Geomembrane Liner Applications

The textured HDPE geomembrane liner is specifically engineered for geotechnical projects that necessitate slope stability. Its high-friction textured surfaces make it an optimal choice for anti-seepage lining, delivering heightened frictional resistance, excellent chemical resistance, and exceptional durability. The textured surface bolsters its capacity to confront slope design challenges, fortifying stability and averting seepage. With its distinctive attributes, the textured HDPE geomembrane liner is well-suited for applications that require augmented frictional resistance, thereby ensuring dependable performance across diverse geotechnical endeavors.

These applications include retaining backfill on steep side slopes, landfill and pad baseliners, heap leach pads, solid waste landfills, hazardous waste landfills, mining operations, coal ash ponds, and animal waste containment. By employing the textured HDPE geomembrane liner, these projects benefit from its ability to mitigate seepage, provide stability against slope-related issues, and maintain performance integrity in the face of various environmental factors. The liner’s tailored design and enhanced frictional properties make it an indispensable solution for geotechnical projects where slope requirements and effective anti-seepage measures are of paramount importance.

6. About GEOSINCERE

GEOSINCERE has been dedicated to manufacturing wholesaling geotexitle and geosynthetics products and solutions to worldwide customers since its foundation in 2007. Our main innovative, high quality products include geotextiles, geomembranes, geogrids, geocells, geosynthetic clay liners, and drainage boards, etc al. GEOSINCERE customers are from more than 1000 countries including America, Australia, France, Sweden, UK, Hong Kong, Hungary, New Zealand, Poland, Mexico, Ecuador, Brazil, Pakistan, Bangladesh, Thailand, Vietnam, Malaysia, Indonesia, Singapore, Philippines, Sri Lanka, India, UAE, Saudi Arabia, Qatar, Kenya, Ghana, Ethiopia, Somalia, Nigeria, South Africa, Swaziland, Mongolia, etc.

GEOSINCERE offers both high quality geosynthetic products but also professional design and installation service. OEM, ODM, custom development and fabrication are also available. If you have any questions or inquiries, please contact us, we will reply as soon as possible.