Geotextile, also known as geotextile fabric, is a permeable material made from textiles. The ASAE defines a geotextile as a fabric or synthetic material placed between soil and structures to enhance water movement and retard soil movement. It adds reinforcement and separation. A geotextile should retain its structure during handling, placement, and long-term service. There are three main types of geotextiles: non-woven, woven, and knitted. They are made from polyester or polypropylene polymers through various manufacturing processes. These geotextiles are used in civil construction applications with foundation, soil, rock, earth, or other materials. Their main functions are to increase soil stability, provide erosion control, and aid in drainage. Geotextiles and their family products like geomembranes, geogrids, and geonets are suitable for geotechnical and environmental construction. GEOSINCERE has been dedicated to geotextile and geosynthetics manufacturing and wholesaling for over 15 years. We also provide geotextile installation services.

What Are 3 Types of Geotextiles

Geotextiles are classified into three primary categories: non-woven, woven, and knitted geotextiles. These types are distinguished by the materials used and their manufacturing processes. Woven geotextiles can be further divided into monofilament and multifilament varieties, as well as slit-film versions of both. Non-woven geotextiles include heat-bonded continuous filaments, needle-punched continuous filaments, staple fibers, resin-bonded fabrics, and combinations thereof. Knitted geotextiles also form part of the non-woven category. Understanding these distinctions is crucial for selecting the appropriate type for specific applications.

- Non Woven Geotextiles

- Woven Geotextiles

- Knitted Geotextiles

Non Woven Geotextiles

Non-woven geotextiles, also known as nonwoven geotextiles or non-woven geotextiles, are made in two different ways. One method uses staple fiber, which is short fibers interlocked together usually by the needle punched manufacturing process. The other method uses continuous filament – long, continuous strands of synthetic fibers that are laid together and bonded by mechanically entangling the fibers. Then, they are needled punched and interlocked to improve strength.

Non-woven geotextiles are commonly available in three colors: white, black, or orange for different applications. Another manufacturing method of non-woven geotextiles is spunbonding. During this process, extruded filaments are spun onto a collecting belt and bonded by applying heated rolls.

Needle punched non-woven geotextiles have a fibrous network with distinctive pores and are very flexible. They typically have high permeability due to their high porosity and conformability because of their high elongation characteristics.

Types of Geotextiles – Applications and Benefits of Non-Woven Geotextiles

Non woven geotextiles filter liquids, preventing soil migration. There are two types of non woven geotextiles. One is staple fiber needle punched geotextile fabric, another is continuous filament geotextile fabric.They’re used in various applications like wrapping pipes and enclosing stones to maintain water flow while blocking soil. These geotextiles are cost-effective alternatives to traditional filters, solving many associated issues. They’re also employed in separation tasks, such as paving patios or walkways. Widely used under HDPE geomembranes, they protect against punctures. Staple fibre needle punched geotextiles are common due to their cost-effectiveness. Manufacturers source staple fibre yarns and invest in custom equipment for production. Continuous filament geotextiles require significant investment and advanced technology, involving the production of synthetic yarns and geotextiles in continuous processes.

Types of Geotextiles – Staple Fibre Needle Punched Geotextiles

Staple fibre needle-punched geotextiles are typically made from short polypropylene or polyester fibers. Polypropylene boasts excellent chemical stability and a favorable cost-to-weight ratio. Conversely, polyester provides superior anti-aging resistance, high creep strength, and tensile strength. This makes it the most cost-effective and widely used geotextile fabric, enhancing the performance and design life of soil or granular layers in various civil, coastal, and environmental engineering projects.

Continuous filament non-woven geotextiles deliver optimal performance per unit weight. They feature high tensile strength and puncture resistance, along with good acid and alkali resistance. Additionally, they offer excellent drainage and anti-aging properties. These geotextiles are extensively used for separation, filtration, drainage, and protection functions in civil, environmental engineering, and construction projects.

GEOSINCERE supplies a wide range of non-woven geotextiles, available in many weights, strengths, and characteristics to meet your specific demands.

Woven Geotextiles

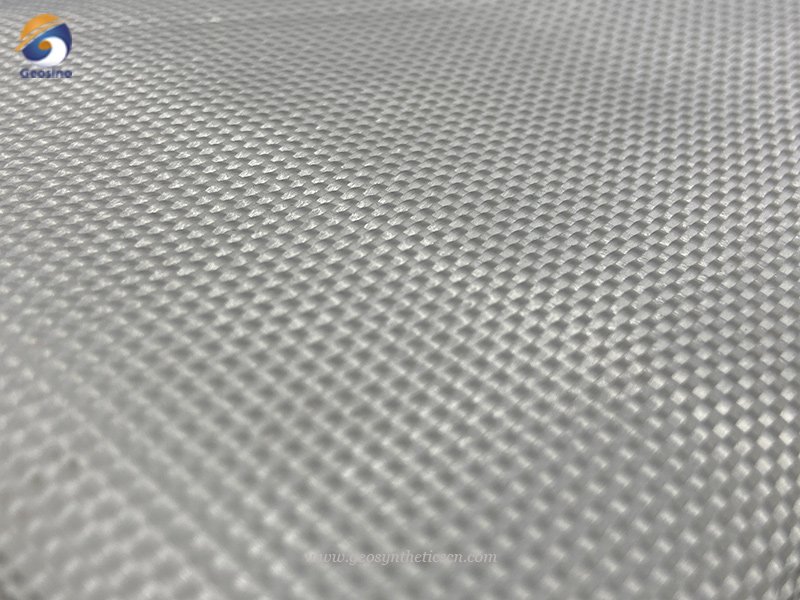

Woven geotextile is a planar, permeable textile made by interlacing elements like yarns and fibers. These elements pass each other to form a stable structure. Woven geotextiles work with soil and rock in engineering projects. They have high tensile strength and low elongation. This makes them ideal for stabilization and reinforcement. They provide dimensional stability and load distribution. They reduce rutting and extend the life of roads. While woven fabrics are relatively impermeable, their high compressive strength suits them for roads and parking lots. They can also be used for filtration due to their permeability. Woven geotextile is measured through trapezoidal tear strength and CBR puncture resistance. The apparent opening size refers to the weave pattern and how fast it drains. Woven geotextile is useful in landscaping and streetscaping. It provides added support as an asphalt overlay or road underlayment.

Main Characteristics and Benefits of Woven Geotextiles

- High tensile strength, Good tear strength

- Good resistance to mineral acids and weak alkalis

- Strengthens and supports aggregates

- Increases performance life of the road

- Withstands tough construction loading

- Disintegrates to strong alkalis and high temperatures

- High permittivity and water flow rates

- Proven performance for most stabilization and reinforcement applications

- Extensive range of size, thickness and grades

- Ease of installation reduces time and labor costs

Polypropylene (PP) and PET are key polymers for woven geotextiles. PP dominates the market, meeting ASTM standards. GEOSINCERE produces high-performance PP and PET woven geotextiles. These materials are lightweight, strong, puncture-resistant, stable, UV-resistant, and stretchable. They provide soil separation, slope support, stabilization, and erosion control. Widely used in roads, pavements, railroads, structures, and water projects.

Knitted Geotextiles

Infrastructure projects in Asia, Europe, and North America are increasingly demanding knitted geotextiles. These textiles, produced by warp-knitting machines, involve interlocking yarn loops. The knitting process uses automated machines with hooked needles to form loops through existing ones. Knitted geosynthetics combine knitting with other manufacturing methods, like weaving. Depending on the process, these textiles offer high tensile strength and elasticity. Their flexibility makes them more economical and effective than other geotextile materials. They improve construction efficiency and effectiveness.

Knitted geotextiles create a planar structure by interlocking yarn loops. They serve as medium, carrier, and interface for various civil engineering applications. In recent years, their role in environmental, constructional, and civil engineering projects has grown. These fabrics manage poor soil, enabling construction in challenging areas. The development of new industrial geotextiles will significantly impact the civil engineering industry, demanding innovation.

About GEOSINCERE

As the professional geotextile and geosynthetics manufacturer and wholesaler, GEOSINCERE is always committed to geotextile research and development, manufacturing and installation services. We can provide our customers with most extensive lines of geotextiles and geomembranes for civil, mining, environmental and aquaculture engineering applications. GEOSINCERE has been keeping on investing in technological innovation, manufacturing facilities improvement and turnkey engineering abilities. Our extensive lines of geosynthetics products are well known for their ensured quality, high performance, excellent durability and best cost effectiveness. GEOSINCERE brand geotextiles and other geosynthetics products and solutions can meet your requirements by our solid technologies, innovative engineering solutions and excellent customer services. Hope to be your partner.

Our main innovative, high quality products include geotextiles, geomembranes, geogrids, geocells, geosynthetic clay Liner, and drainage boards, etc al. GEOSINCERE customers are from more than 100 countries.

GEOSINCERE offers both high quality geosynthetic products but also professional design and installation service. OEM, ODM, custom development and fabrication are also available. If you have any questions or inquiries, please contact.