You’ve likely seen geotextile fabric while you’ve been out and about, or maybe you’ve even used it at some point on your property. The permeable material can be non woven or woven geotextile, each type getting used for a variety of applications. For example, non woven geotextile is used for things like retaining walls and sandbags, while woven geotextile is ideal for driveway construction and erosion control projects. However, uses for woven and nonwoven geotextile can vary depending on various project scopes. Both are typically known for perks such as offering soil stability and drainage.As the leading geosynthetics manufacturer and supplier, GEOSINCERE offer various types geotextile with custom thickness and size at best factory price.Let’s discuss it together – Ultimate Comparison Of Woven vs Non Woven Geotextile.

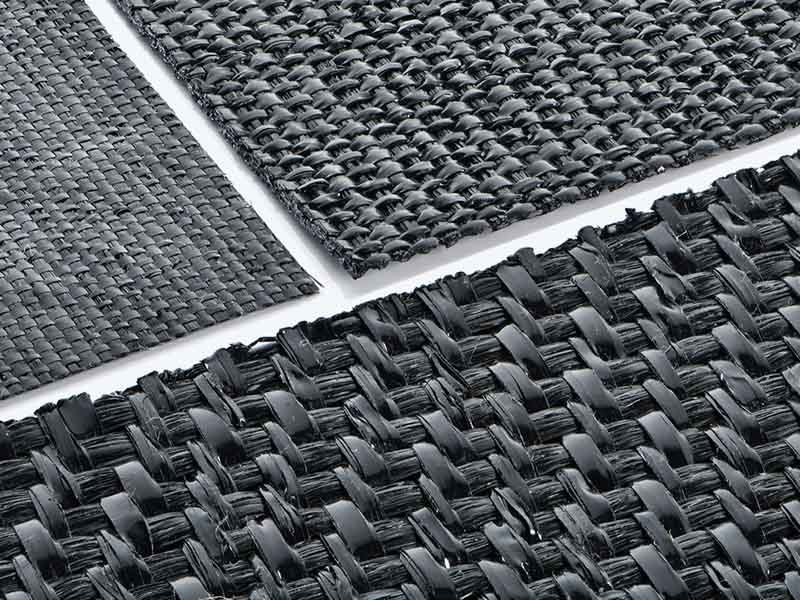

1. What Is Woven Geotextile?

Woven geotextiles, made by weaving polypropylene or polyester fibers, offer strength, stability, and reinforcement in civil engineering and geotechnical applications. Woven geotextiles are mainly made of flat wire cut from polypropylene (PP) blown film on a circular loom. They are characterized by low cost and tensile strength more than twice that of non-woven geotextiles. They are the preferred materials for isolation, reinforcement and reinforcement.Their interlocking fiber structure creates durable fabrics, available in rolls of different sizes for easy installation. These geotextiles primarily stabilize and separate soil layers, maintaining soil integrity and facilitating filtration and drainage. They find widespread use in road construction, embankments, retaining walls, erosion control, and other civil engineering projects. Depending on project requirements, geotextiles with specific tensile strength, permeability, and filtration properties can be selected.

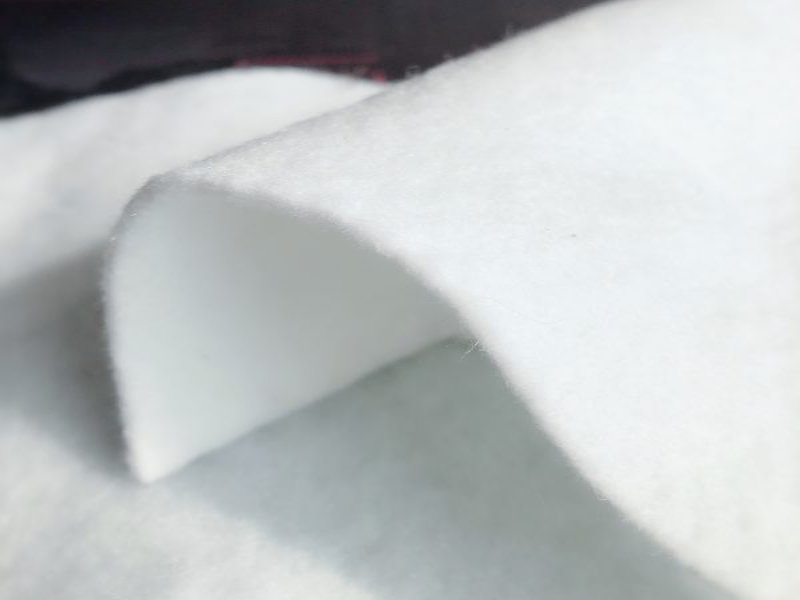

2. What Is Non Woven Geotextile?

Non-woven geotextile is a geosynthetic material created by bonding or felting synthetic fibers together. Unlike woven geotextiles, they have a random fiber arrangement and offer excellent filtration, drainage, and separation properties. These geotextiles are widely used in civil engineering and geotechnical applications to stabilize soil, control erosion, and enhance load-bearing capacity. They are versatile and find application in road construction, embankments, landfills, drainage systems, and erosion control projects.

Non-woven geotextiles provide functions such as soil stabilization, filtration, and protection. They allow water to pass through while retaining soil particles, maintaining the integrity of the soil structure. The selection of non-woven geotextiles depends on factors like tensile strength, permeability, and project requirements. With different grades and specifications available, non-woven geotextiles offer a reliable solution for improving geotechnical structures and ensuring long-term performance.

3. Major Differences Between Woven vs Non Woven Geotextile

Woven and non woven geotextiles have significant differences, especially in their applications and how they are manufactured. The kind of project you are working on will determine the geotextile fabrics that will best suit you. Listed below are the major difference between woven and non woven geotextiles:

3.1 Manufacturing Process

- Woven Geotextile: Woven geotextiles are created by interlacing polypropylene or polyester fibers together through a weaving process, forming a structured and uniform fabric.

- Non woven Geotextile: Nonwoven geotextiles are produced by bonding or felting synthetic fibers together through mechanical or chemical processes, resulting in a random arrangement of fibers without weaving.

3.2 Physical Characteristics

- Woven Geotextile: Woven geotextiles have a high tensile strength and are relatively rigid due to the interlocking woven fibers. They offer excellent dimensional stability and resistance to deformation.

- Non woven Geotextile: Nonwoven geotextiles have lower tensile strength compared to woven geotextiles. They are flexible, lightweight, and have good elongation properties. Their random fiber arrangement provides high permeability and filtration capabilities.

3.3 Applications

- Woven Geotextile: Woven geotextiles are commonly used for applications requiring high strength and separation. They are ideal for soil stabilization, reinforcement, and separation in applications such as road construction, embankments, and retaining walls.

- Non woven Geotextile: Nonwoven geotextiles are versatile and suitable for various applications. They are often used for filtration, drainage, and erosion control. They are commonly found in applications such as drainage systems, landfills, and erosion control projects.

3.4 Cost

- Woven Geotextile: Woven geotextiles are generally more expensive due to the weaving process and higher tensile strength.

- Non woven Geotextile: Nonwoven geotextiles are typically more cost-effective due to their simpler manufacturing process and lower material costs.

4. The Main Similarities Between Woven vs Non Woven Geotextile

While woven and nonwoven geotextiles have distinct characteristics, they also share some similarities, including:

4.1 Geotechnical Functions

Both woven and nonwoven geotextiles serve important functions in civil engineering and geotechnical applications. They are used to stabilize soil, prevent erosion, improve drainage, and provide separation between soil layers.

4.2 Versatility

Woven and nonwoven geotextiles are versatile materials that can be used in a wide range of applications. They find use in road construction, embankments, retaining walls, landfills, drainage systems, erosion control, and other civil engineering projects.

4.3 Installation Flexibility

Both types of geotextiles are typically supplied in rolls of varying widths and lengths, allowing for easy transportation, handling, and installation. This flexibility enables them to be adapted to different project requirements and site conditions.

4.4 Compatibility with Soils

Woven and nonwoven geotextiles are compatible with various types of soils, including cohesive soils, granular soils, and mixed soil compositions. They can be effectively used in different soil conditions to enhance the performance of geotechnical structures.

5. Summary

In summary, woven geotextiles have a structured and rigid fabric with high tensile strength, while nonwoven geotextiles have a random fiber arrangement, lower tensile strength, and higher permeability. Woven geotextiles are suitable for applications requiring strength and separation, while nonwoven geotextiles excel in filtration, drainage, and erosion control. GEOSINCERE always tries our best to solve the most complex civil, mining and environmental challenges with our innovative and high performance geosynthetic products. Quality assurance, factory price and fast delivery time are our competitive advantages.

If you have any questions or inquiries, please contact us, we will reply as soon as possible.