As an important civil engineering material, HDPE geomembrane plays an important role in seepage control, waterproofing and protection. According to the different surface treatments, HDPE geomembranes can be categorized into textured geomembranes and HDPE smooth geomembranes. GEOSINCERE Geosynthtics is leading HDPE geomembrane liner manufacturer and supplier, we wholesale geomembrane liner ar competitive factory price. In this paper, the similarities in material/properties as well as the differences in performance and application of these two types of geomembranes will be compared in detail to help engineers and related decision makers to make a more informed decision in their selection.

1 What Are Similarities Between HDPE Smooth Geomembrane and Textured Geomembrane

1.1 HDPE Smooth And Textured Geomembrane are Made of Polymer Materials

Whether HDPE smooth geomembrane or textured geomembrane, their main materials are polyethylene or polyvinyl chloride and other polymer materials. The most common use material is HDPE/LDPE/LLDPE. These materials have excellent weather resistance, chemical resistance and anti-aging properties. Especially the HDPE.

GEOSINCERE High Density Polyethylene (HDPE) geomembrane liners have excellent resistance to aging, chemicals, environmental stress cracking and puncture, as well as good temperature adaptability, weldability and weatherability. These properties make HDPE geomembrane liners a high-performance civil engineering material capable of adapting to a variety of complex environmental conditions.

1.2 With Similar Physical Properties

Both HDPE smooth geomembrane and textured geomembrane have high strength and good abrasion resistance, and can withstand friction and pressure from soil or other materials. In addition, they both have good stability and weather resistance under the condition of temperature change or climate change.

1.3 Similar Chemical Properties

Both HDPE smooth geomembrane and textured geomembrane have good chemical resistance, are able to resist the erosion of soil chemicals, moisture, oxygen and so on. Stability in the chemical environment are higher, not easy to chemical reaction with the soil or other substances.

1.4 Similar Waterproof Performance

Both HDPE smooth geomembrane and textured geomembrane have a certain degree of waterproof performance, to prevent infiltration of soil or other substances.

1.5 Similar construction performance

In the construction process, HDPE smooth geomembrane and textured geomembrane are easy to lay and fix, with better construction performance.

2 What Is Differences Between HDPE Smooth vs Textured Geomembranes

2.1 Differences in Performance Advantages

2.1.1 Performance Advantages of HDPE Smooth Geomembranes

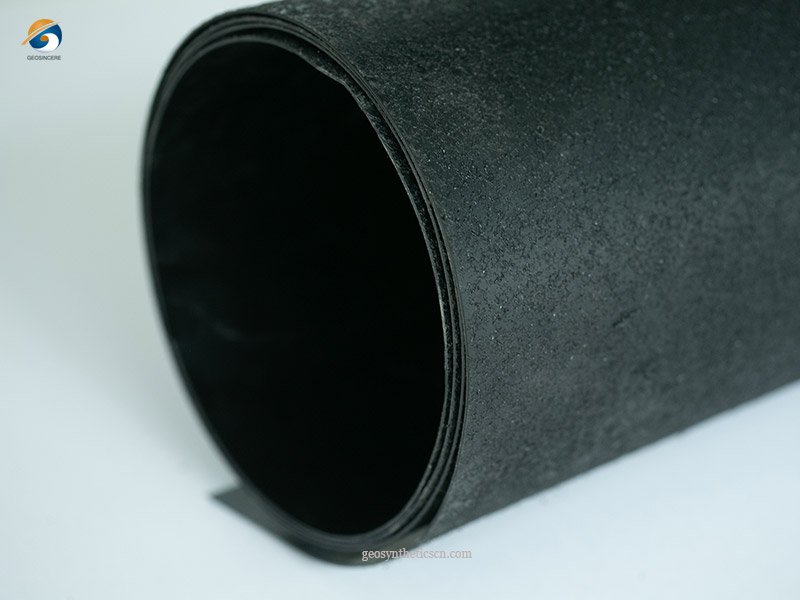

- Easy construction.The HDPE Smooth surface makes the geomembrane easier and faster to lay and shortens the construction period. Its construction efficiency is usually higher than textured geomembrane. GEOSINCERE smooth HDPE geomembrane is fabricated by the state-of-the-art automatic geomembrane production lines and advanced three layered pressing technology in accordance with GRI GM13 standard.

- Lower cost.The production process of HDPE Smooth geomembranes is relatively simple, which reduces production costs and is suitable for large-scale projects. Its price is usually more economical than textured geomembranes.

- Good weatherability.HDPE Smooth surfaces are not easily affected by UV rays, wind and rain, and other natural factors, and have good weatherability. Its weathering performance is usually better than that of textured geomembranes, and it is suitable for projects that need to be exposed to the natural environment for a long time.

- Good chemical corrosion resistance.the HDPE Smooth surface is not easy to have chemical reaction with soil or other substances, which improves the durability of geomembrane. Its chemical resistance is usually better than that of textured geomembrane, and it is suitable for projects that need to be exposed to chemical substances.

2.1.2 Performance Advantages of Textured Geomembranes

- Increased coefficient of friction.Textured geomembrane has uneven texture on its surface, which can provide greater friction when contacting with soil or other materials, effectively preventing sliding and displacement. Its coefficient of friction is usually 0.5 to 0.8, compared with the coefficient of friction of HDPE Smooth geomembrane of 0.3 to 0.4, which has higher anti-slip performance. GEOSINCERE provides high quality custom textured geomembrane with competitive factory price.

- Enhanced drainage performance. The textured design helps water to flow through quickly, improves drainage efficiency, and prevents problems such as soil erosion and landslides. Its drainage performance is usually better than that of HDPE Smoothgeomembranes, and it is suitable for situations that require rapid drainage.

- Improved aging resistance.Textured surfaces are less likely to adhere to stains, soil and other impurities, reducing maintenance costs and frequency. Its aging resistance is usually better than that of HDPE Smooth geomembranes, and it is suitable for projects that require long-term weathering.

- Improved visual effect. The textured design makes the geomembrane more visually attractive and improves the aesthetics of the project. Its appearance is usually more beautiful than HDPE Smooth geomembranes.

2.2 Differences in Application Scenarios Between HDPE Smooth vs Textured Geomembranes

2.2.1 Application Scenarios for HDPE Smooth Geomembranes

- Foundation engineering.In foundation engineering, such as foundation treatment, road base, etc., HDPE Smooth geomembrane can provide good impermeability and weather resistance to ensure the stability and durability of the foundation. It can be used in the construction of bridges, roads and other infrastructure.

- Water conservancy projects.In water conservancy projects, such as dams, reservoirs, etc., HDPE Smooth geomembrane can provide reliable seepage protection to ensure the safe operation of water conservancy facilities. It can be used as waterproof layer and protective layer of water conservancy project.

- Environmental protection projects.In environmental protection projects, such as sewage treatment plants, landfills, etc., HDPE Smooth geomembrane can provide good chemical corrosion resistance and weather resistance, to ensure the stable operation of environmental protection facilities. It can be used in the construction and renovation of environmental protection facilities.

- Agricultural field.In the agricultural field, such as greenhouses, irrigation channels, etc., HDPE Smooth geomembrane can provide good seepage control and weathering performance, improve the service life and efficiency of agricultural facilities. It can be applied in the construction and renovation of agricultural facilities.

2.2.2 Application Scenarios for Textured Geomembranes

- Slope protection.In slope protection projects, textured geomembrane can provide excellent friction and drainage performance to effectively prevent soil erosion and landslides. It is widely used in mountainous areas, riverbanks and other projects that need to prevent soil erosion.

- Landfill.leachate treatment in landfill is the key link, textured geomembrane has excellent seepage control performance and aging resistance, suitable for landfill seepage control project. It can effectively prevent the leakage and spread of leachate.

- Reservoir dams.The seepage control project of reservoir dams is crucial to ensure the safety of water conservancy, and textured geomembranes can provide reliable seepage control protection. It can be used in seepage control projects of reservoirs, dams and other water conservancy facilities. Real cases reference: For the reservoir project in Kenya, after the analyzing by GEOSINCERE experts with clients, we chose the1.5mm HDPE textured geomembrane for as the pond liners.

- Underground engineering.in underground engineering, such as subways, tunnels, etc., textured geomembrane can provide good seepage control and drainage performance, to ensure the safety and stability of the project. It can be used as the waterproof layer and protective layer of underground engineering.

3 Conclusions

Textured geomembranes and HDPE Smooth geomembranes each have their own performance advantages and application scenarios. When choosing to use them, comprehensive consideration should be made according to the actual needs of the project. For the occasions that need larger friction coefficient, strong drainage performance and good anti-aging performance, it is recommended to choose textured geomembrane; while for the occasions that need easy construction, lower cost, good weathering and chemical corrosion resistance, it is recommended to choose HDPE Smooth geomembrane. At the same time, in the construction process should pay attention to the construction quality control and maintenance work to ensure the normal use of geomembranes and extend the service life.

Any questions about how to choose HDPE Smooth vs textured geoemmbrane, contact us at any time.

Thanks for reading.