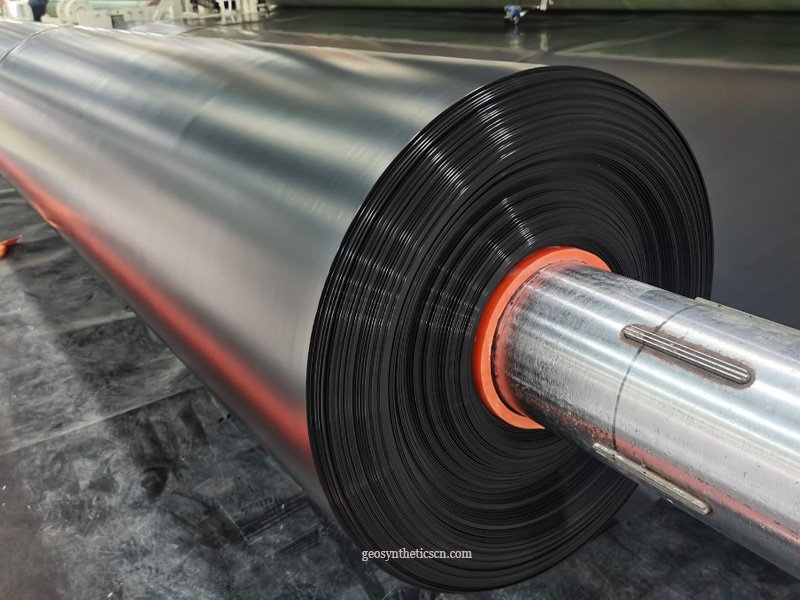

HDPE liner is a kind of geomembrane liner made from high-density polyethylene (HDPE) resin. HDPE liner is a impermeable synthetic membranes which mainly used in civil engineering,and industrial applications for containment, lining, and protection projects as mining landfill etc.

GEOSINCERE is the professional HDPE liner manufacturer and supplier, we offers a wide range of geomembrana products including smooth HDPE geomembrane, textured geomembrane and composite geomembrane at best factory price.

1. What Is HDPE Liner?

High-Density Polyethylene (HDPE) liners are specialized geomembranes primarily used in environmental containment projects. They commonly create landfill liners, pond liners, and other scenarios where liquid or gas containment is crucial. HDPE liners have exceptional thickness, ranging from 20 mils (0.5 mm) up to 120 mils (3 mm), making them the thickest among liner options.

They are extensively used in tasks such as creating landfill liners, pond liners, lagoon liners, and industrial storage ponds. These liners act as impermeable barriers, preventing the migration of liquids or gases and protecting soil and groundwater from contamination.

The installation process for HDPE liners typically involves unrolling them onto a prepared surface and securing them in place. The liner panels are then joined together using techniques such as thermal welding or seaming. This creates strong and watertight seams that enhance the overall integrity of the liner system.

HDPE liners often meet or exceed required standards for environmental containment. They are designed to provide a reliable and compliant solution for containing hazardous substances, ensuring environmental protection and adherence to regulations.

2. For its main following characteristics, HDPE Liner is the crucial material

2.1 Material Composition

HDPE liners are manufactured from high-density polyethylene resin, a thermoplastic polymer and as it has excellent chemical resistance, puncture resistance durability, and flexibility in installation. HDPE is derived from petroleum and is commonly used in geomembrane applications due to its favorable properties.

2.2 Impermeability

HDPE liners are highly impermeable to liquids, gases, and contaminants, making them effective barriers for containing fluids and preventing environmental contamination. Their low permeability ensures reliable containment of water, chemicals, and hazardous substances.

2.3 Flexibility and Conformability

HDPE liners exhibit excellent flexibility and conformability, allowing them to adapt to irregular surfaces and terrain contours. This flexibility facilitates ease of installation and ensures a secure fit, even in challenging environments.

2.4 Chemical Resistance

HDPE liners are resistant to a wide range of chemicals, including acids, alkalis, solvents, and hydrocarbons. This chemical resistance makes HDPE liners suitable for applications where exposure to aggressive substances is expected, such as industrial wastewater treatment facilities and hazardous waste containment sites.

2.5 UV Resistance

HDPE liners can be manufactured with UV stabilizers to enhance resistance to ultraviolet (UV) degradation. This UV resistance ensures long-term durability and performance in outdoor applications where geomembranes are exposed to sunlight.

2.6 Tensile Strength and Tear Resistance

HDPE liners exhibit high tensile strength and tear resistance, providing mechanical strength and durability for long-term performance in demanding applications. They can withstand stress, puncture, and tearing caused by external forces and environmental factors.

2.7 Seaming and Weldability

HDPE liners can be heat-welded or fused together to create strong and durable seams and joints. This welding capability allows for the construction of large-scale containment systems without the need for additional fasteners or adhesives.

2.8 Environmental Compatibility

HDPE liners are inert and chemically stable, posing minimal risk of leaching harmful substances into the surrounding environment. They are commonly used in environmental protection projects, such as landfill liners, pond liners, and secondary containment systems.

3. What Is HDPE liner Used For?

The most popular applications for HDPE Liner including:

3.1 Environmental Containment

HDPE liners play a crucial role in various containment applications, including landfills, waste storage facilities, and industrial sites. In landfills, they serve as primary and secondary barriers to prevent leachate migration. Transitioning to waste storage facilities, HDPE liners are used to contain toxic substances in hazardous waste storage ponds and lagoons. Additionally, at industrial sites, these liners line tanks, ponds, and basins to contain chemicals and wastewater.

3.2 Water Management

HDPE liners are used to prevent seepage and water loss in ponds, reservoirs, and water storage facilities for agriculture, aquaculture, irrigation, and conservation. Moving on to canal and irrigation systems, HDPE liners reduce water seepage and improve efficiency. Additionally, in stormwater management, HDPE liners help manage runoff, prevent erosion, and control pollution in detention basins, retention ponds, and drainage ditches.

3.3 Mining and Industrial Applications

HDPE liners contain mine tailings in Tailings Storage Facilities (TSFs) to prevent environmental harm. They are also used to line heap leach pads, containing leach solutions and preventing soil and water contamination. Additionally, in the oil and gas industry, HDPE liners serve as secondary containment for drilling fluids, production water, and wastewater during various activities.

3.4 Agriculture and Aquaculture

HDPE liners are used in agricultural ponds and reservoirs to store irrigation water and farm wastewater. Additionally, in aquaculture, HDPE liners create an impermeable barrier to control water quality.

3.5 Civil Engineering and Construction

HDPE liners provide waterproofing and protection against water in tunnels and underground constructions. Additionally, they are used in geotechnical projects for slope stabilization, soil erosion control, and groundwater protection. Overall, HDPE liners offer versatile and durable solutions for various industries, ensuring effective containment, protection, and environmental management.

4. How To Use HDPE Liner For Mining Projects?

The function of HDPE liner in a Tailings Storage Facility (TSF) is primarily to provide a robust and impermeable barrier that contains and isolates mine tailings, preventing their release into the surrounding environment.

4.1 The design of Tailings Storage Facility using HDPE Liner

As we all know that the design of the mining TSF ,Tailings Storage Facility (TSF), it typically consists of various components designed to safely contain, manage, and store the waste materials generated during the mineral extraction and processing processes. While TSF designs can vary depending on site-specific factors, the following are common components found in the structure of a TSF:

-

Tailings Storage Area

This is the primary area where the mine tailings are deposited and stored. It may consist of one or multiple containment cells, each designed to hold a specific volume of tailings. The storage area is often constructed with embankments, berms, or retaining walls to create containment cells.

-

Liner System

A liner system is installed within the tailings storage area to create an impermeable barrier that prevents seepage of tailings and contaminated water into the surrounding environment. This liner system typically includes geomembranes (such as HDPE liners) and geosynthetic clay liners (GCLs) to provide effective containment.

-

Overflow and Spillway Structures

These structures are designed to manage water levels within the TSF and prevent overtopping or breaches during periods of heavy rainfall or high water flow. They may include spillways, weirs, or emergency overflow channels to safely discharge excess water.

-

Water Management Infrastructure

TSFs often include infrastructure for managing excess water generated within the facility, such as drainage channels, collection ponds, and water treatment facilities. This infrastructure helps control water levels, mitigate the risk of water contamination, and ensure compliance with regulatory requirements.

-

Monitoring and Control Systems

TSFs are equipped with monitoring and control systems to track key parameters such as water levels, settlement, and liner integrity. These systems may include sensors, gauges, and automated monitoring equipment to detect and respond to potential risks or issues in real-time.

-

Access Roads and Infrastructure

Access roads and infrastructure are constructed to provide access to the TSF for operational activities, maintenance, and monitoring. These may include roads, bridges, and platforms for equipment and personnel access.

-

Closure and Rehabilitation Plan

TSFs are designed with closure and rehabilitation plans to guide the decommissioning and remediation of the facility once mining operations cease. This may involve measures such as regrading, revegetation, and long-term monitoring to restore the site to a safe and stable condition.

4.2 What is the functions of HDPE liner in a TSF?

-

Containment of Mine Tailings

HDPE liners create a reliable barrier that contains the mine tailings within the storage facility. This prevents the dispersion of potentially harmful substances into the surrounding soil, groundwater, and surface water bodies.

-

Prevention of Contamination

By effectively isolating mine tailings, HDPE liners help prevent contamination of the environment with heavy metals, chemicals, and other pollutants present in the tailings. This protects ecosystems, aquatic habitats, and human health from adverse effects of contamination.

-

Groundwater Protection

HDPE liners serve as an impermeable barrier that prevents seepage of contaminated water from the TSF into underlying groundwater aquifers. This helps safeguard groundwater resources and prevents contamination of drinking water sources.

-

Minimization of Environmental Risks

HDPE liners minimize the risk of environmental incidents and accidents associated with TSFs by providing a secure containment system for mine tailings. This reduces the potential for environmental damage and adverse impacts on biodiversity and ecosystems.

-

Stability and Structural Integrity

HDPE liners contribute to the stability and structural integrity of the TSF by providing reinforcement and support for the containment system. This helps maintain the overall stability of the facility and reduces the risk of liner failure or breaches.

-

Long-Term Durability

HDPE liners are designed to withstand the harsh conditions and dynamic forces present in TSFs, including exposure to chemicals, UV radiation, temperature fluctuations, and mechanical stresses. Their long-term durability ensures reliable performance and containment over the lifespan of the TSF.

-

Ease of Installation and Maintenance

HDPE liners are relatively lightweight and flexible, facilitating ease of installation and construction in TSFs of various sizes and configurations. They also require minimal maintenance, contributing to cost-effectiveness and operational efficiency.

5. Summary

HDPE liner plays a critical role in the safe and sustainable management of mine tailings in TSFs, providing essential containment and environmental protection measures to mitigate risks and ensure compliance with regulatory requirements. Their impermeable properties, durability, and reliability make them a preferred choice for lining applications in the mining industry.

As the professonal geosynthetics manufacturer and supplier, GEOSINCERE wholesales best HDPE geomembrane liner at factroy price.

Any questions, please contact us.